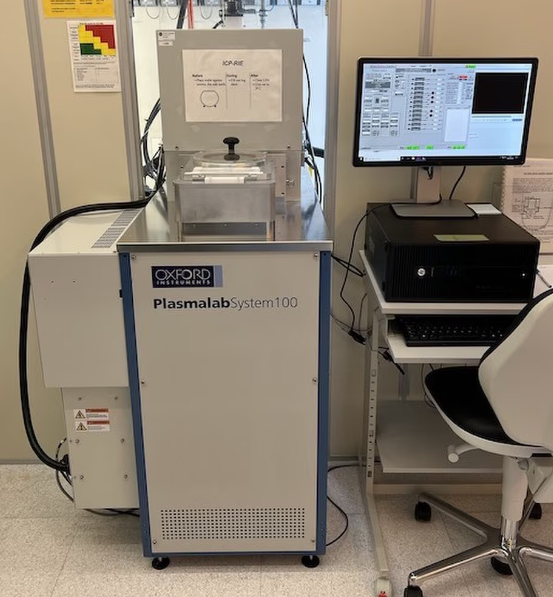

Oxford Plasmalab 100 ICP

AMERICA North (USA-Canada-Mexico)

OXFORD PLASMALAB 100 ICP ETCHER consisting of:

- Manufacturer: Oxford Instruments

- Model: Plasmalab System 100 ICP-RIE 180

- Process gases used: H2, O2, N2, Ar, CF4, SF6, CHF3,

He, CH4, HBr, Cl2 and BCl3

- Cryo Table w/ operating temp: -150 to 400C

- Substrate cooling: using liquid nitrogen (LN2)

- RF source 300 W, 13.56 MHz

- ICP source 3000 W, 13.56 MHz

- Base pressure: 5E-7 Torr

- Horiba Laser Endpoint Detector

- Load Locked

Pumps:

Main Chamber Backing Pump:

- Manufacturer: Adixen

- Type: Dry pump (multi roots)

- Model: ADP 122 P

Main Chamber Turbo Pump:

- Manufacturer: Adixen

- Type: Turbo

- Model: ATH 1300

Load Lock:

- Manufacturer: Adixen

- Type: Dry pump (multi roots)

- Model: ACP 15G

REFURBISHED TO MEET OEM SPECIFICATIONS consisting of:

- Chamber disassembled for refurbishment.

- Chamber received full wet clean.

- Chamber o-rings and seals are replaced with brand new.

- Electrostatic Chuck (ESC) sent out for refurbishment (if applicable)

- All MFCs rebuilt and calibrated professionally.

- All corrosive gas lines replaced with brand new.

- All Non-corrosive gas lines cleaned.

- Vacuum pumps professionally rebuilt.

- Turbo pump professionally rebuilt.

- Chillers serviced and fully tested.

- All wiring/wire harnesses are checked, repaired or replaced if needed.

- All liquid and air lines, tubing and fittings checked and

replaced if necessary.

- Major components disassembled for checkout, servicing, cleaning,

and lubricating. Parts are repaired or replaced as needed.

- Checkout of all electronic and mechanical parts.

- Machine covers are cleaned, polished or replaced as needed.

- Equipment is fully tested to verify compliance to specifications.

- Post-refurbishment system leak and RF calibration checks,

with documentation provided to customer.

- System cycle and repeatability testing completed prior to

cover replacement and wipe down.

- System components carefully packed, labeled, and professionally crated.