Allwin21 AW 4450 Sputter ([email protected])

AMERICA North (USA-Canada-Mexico)

Please visit our website for updated information at www.allwin21.com

Updated Brochure in2024:https://allwin21.com/wp-content/uploads/2024/05/Allwin21-Product-Brochures-Sputtering-Deposition-2024.5-1.pdf

Why Allwin21 AccuSputter AW4450 Sputtering Deposition Eqyupment: https://allwin21.com/wp-content/uploads/2024/05/AccuSputter-AW-4450-Sputtering-Deposition-Equipment.pdf

AW 4450 Sputter

Wafer Size: Small~8 inch

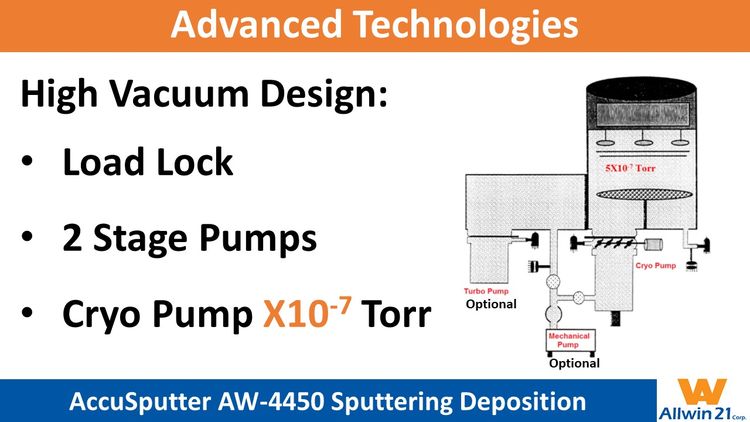

Wafer loading: Manual, with Load Lock

Cathodes: 3xDelta Shape OR 4xCircle Shape

Sputter Methods: RF/DC; Diode/Magnetron

Gas Lines: 1~3 MFCs

Features

Process Proven for III-V substrates

Non-PLC (Smaller footprint / easy maintenance)

20+ years proven sputter technology

New optimum AW-4450 System Control

DC 24V for Motors,Actuator,Relay,Solenoid

Efficient 8″ ,Delta cathodes, 2 to 6″ option

High throughput operation

High Uniformity and Yield

DC, RF Sputter, Pulse DC option

Magnetron and Diode Sputter option

RF Etch and Bias are optional

Ultra Clean vacuum system

Load lock operation

UHV design

Flexible for development or production use

Full range of substrate sizes and shapes

Various pumping and power options

Co-sputtering option

Allwin21 Corp. has been focusing on providing solutions and enhancements to Perkin-Elmer 4400, Perkin-Elmer 4410, Perkin-Elmer 4450, Perkin-Elmer 4480 used sputter deposition semiconductor processequipment. These OEM semiconductor equipment have been used in productions and R&D since 1990′s. They have been proven to be a true “work horse”. Allwin21 Corp. can customize these OEM systems with Allwin21′s comparable integrated process control system with PC and new critical components. We rebuild AccuSputter AW 4450 Series Sputter Deposition systems with our own integrated process control system, giving our customers the tools to achieve a production edge at very low cost impact.