6 Allwin21 AW-901eR , AW-903eR - [email protected]

AMERICA North (USA-Canada-Mexico)

Please visit our website for updated information at www.allwin21.com

Updated Brochure in2024:https://allwin21.com/wp-content/uploads/2024/05/Allwin21-Product-Brochures-Plasma-Etcher-2024.5-1.pdf

Why Allwin21 AW-901eR , AW-903eR Semiconductor front end plasma etcher equipment: https://allwin21.com/wp-content/uploads/2024/05/AW-90XeR-Plasma-Etcher-RIE.pdf

Brand: Allwin21 Corp.

Allwin21 Corp. AW-901e Plasma Etch RIE

Wafer Size: 3″ – 6″ Capability

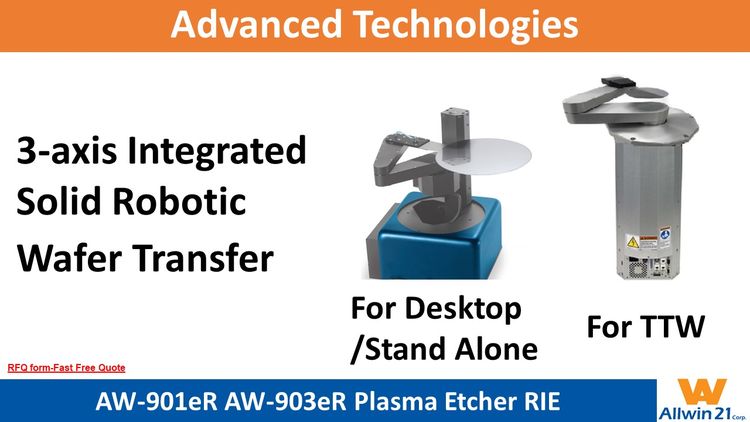

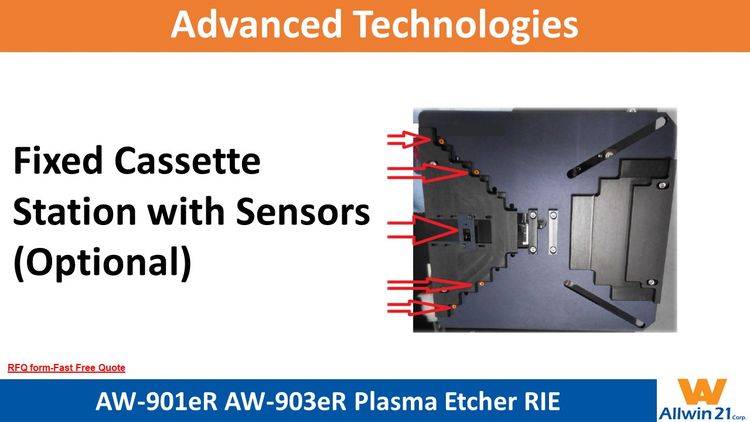

Wafer Loading: 3-axis Robot; Stationary Cassette Plate

Plasma Power: RF 13.56MHz

Type: Parallel/Single Wafer Process; Stand-Alone

Gas Lines: 1-3 Lines

Features:.

PROCESS AND PRODUCTION PROVEN reactor chamber assembly with upper and lower electrode.

Handles 75mm,100mm, 125mm, 150mm Silicon or III-V wafers ,round.

Robotic 3-axis wafer transfer TO PREVENT WAFER BREAKAGE.

4 independent gas line with 4 MFCs (Customized)

Processing of substrate directly on cooled wafer chuck

13.56MHz fully automated RF matching network

ENI ACG-10B 13.56MHz or Equivalent (Water Cooled). Air-Cooled RF Generators are optional.

Accurate, closed-loop pressure control with UPC and MKS Baratron capacitance manometer

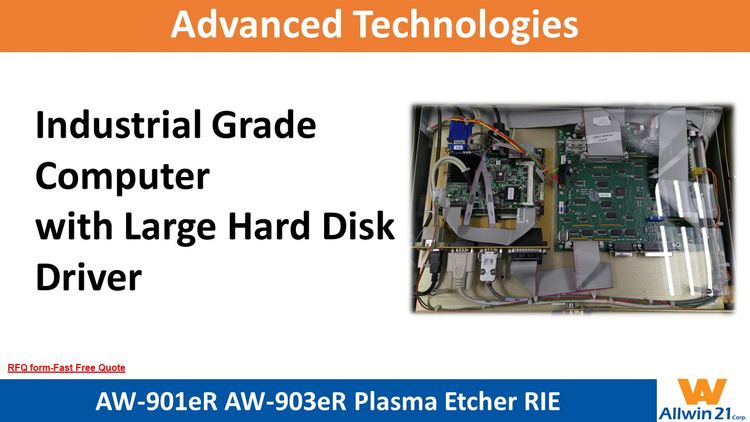

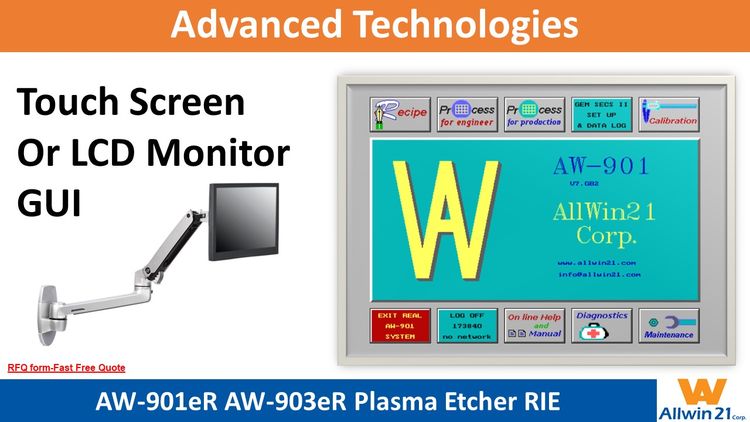

Touch screen monitor or LCD Monitor with PC.

New AW-901e Control System from Allwin21 Corp.

Gas flows: settings for up to 4 independent mass flow controller values

RF power: 50 to 1000 watts

Process pressure

Absolute endpoint time

Timed cycles up to 4 hour each

Wafer pins up/down

Optical Endpoint Parameters

Automated calibration of all subsystems

Trouble shooting to subassembly levels

Programmed comprehensive calibration and Built-in diagnostic functions

Recipe creation for full automatic wafer processing

Automatic decline of improper recipes and process data

Multi level pass word protections

Storage of multiple recipes and system functions

Real-Time process data acquisition, display ,analysis

Real-Time graphics display

Process Data and Recipe storage on a hard drive

Allwin21 Corp. has been focusing on providing solutions and enhancements to Tegal 901e, Tegal 903e, Tegal 901e TTW, Tegal 903e TTW used plasma Etch RIE semiconductor process equipment. These OEM Etch RIE semiconductor equipment have been used in productions and R&D since 1990′s. They have been proven to be a true “work horse”. Allwin21 Corp. can customize these OEM systems with Allwin21′s comparable integrated process control system with PC, solid robotic wafer transfer system (Video) and new critical components to achieve the goal of giving our customers a production edge with right cost.