Manncorp MCLEDV6 High Speed LED Pick & Place

AMERICA North (USA-Canada-Mexico)

Assemble LED lighting products, including long tube boards and

flexible strips, at rates reaching 30,000 LEDs per hour,

with a high-speed, dedicated LED placer.

The MCLEDV6 has a 23.6" (600 mm) max board length and

includes automatic, on-the-fly full vision alignment.

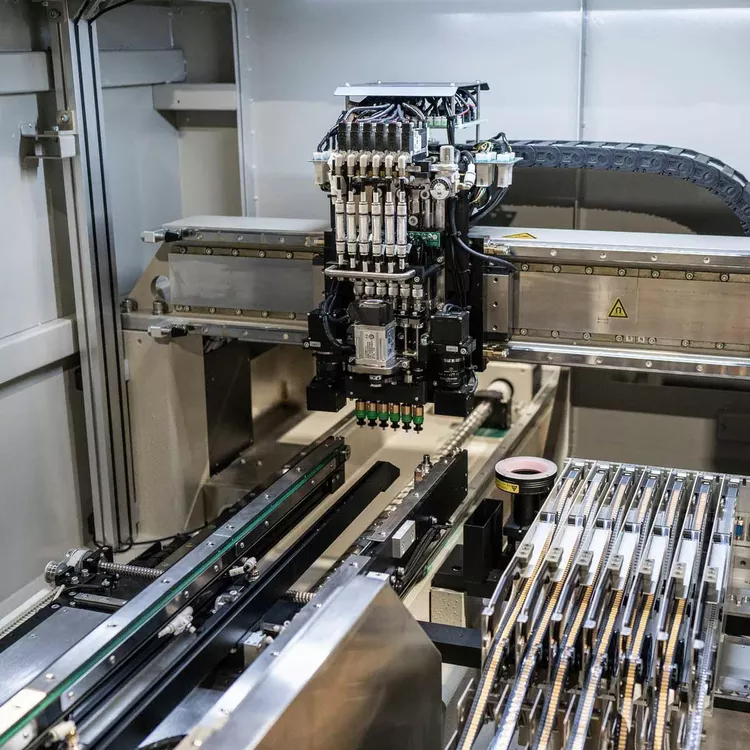

High-Speed, High-Efficiency Design

The 6-head MCLEDV6's high speed linear drive gantry

performs simultaneous pick-up to achieve rates of

30,000 LEDs per hour (per IPC-9850 standard).

True fly-over alignment,

with an upward-looking camera located between the

feeder base and PCB, aligns components while the head is

in motion.

Thanks to the included software,

feeder locations are also optimized prior to

placement to minimize head travel and

tool changes.

Specifically Designed for LED Assembly

Unlike standard pick and place machines that

have been adapted to LED assembly,

the MCLEDV6 is purpose-built specifically to

build LED boards.

The MCLEDV6 places LED components from

0402 to 20 mm x 18 mm, including both standard and irregularly shaped LEDs to small connectors or resistors.

Each of the MCLEDV6's six placement heads features

positive air pressure to release 'sticky' LED components.

Non-stick, Teflon®-coated nozzles—

including custom nozzle designs—

are also available.

Rounded LEDs can be safely placed using

placement nozzles designed to not meet the

optical lens during pick-up, protecting the

component's overall performance and reliability.

Options For All LED Lighting Products

Flexible PCB strips, circular LED light bulb boards and

even irregularly shaped boards can also be assembled quickly,

accurately, and reliably on all models in the MCLED-series.

With all models, the full length of the board is

assembled in a single pass for top efficiency and throughput.

For long LED tubes, model MCLEDV6-12 features

a max board size of 47.3" (1200 mm).

The MCLEDV6 comes standard with a worktable and

magnetic board fixture or can be configured at

time of purchase with a SMEMA-compatible inline conveyor for automation.

Software Simplifies Production

Several powerful software tools are included with

the MCLEDV6 system, including the UCAD®

universal CAD import/conversion utility to

simplify placement programming,

a feeder arrangement optimizer to

minimize head travel and tool changes,

and real-time monitoring of production that

gives the operator at-a-glance information.

Easily monitor production with a virtual view of

products under assembly, along with placement rate,

placement time, and production count.

Companies that already have one or

more MC-series machines in

their facility will find the MCLEDV6's software

interface immediately familiar, which means zero

learning curve when it comes to programming and

operating.

24/7 Workhorse

The MCLEDV6 offers nonstop production.

Its ability to automatically switch to

a different feeder when an in-use one runs out of

components allows operators to refill empty feeders without

taking production offline.

Up to 16 special, servo-driven feeders can

be used with the MCLEDV6.

Brushless motors promote a longer feeder life

under around-the-clock production conditions.

And with these feeders, it is also possible to

splice a new reel onto an old one for

minimizing production interruption.

PLACEMENT SPECIFICATIONS

Number of Placement Heads 6

Placement Rate (IPC-9850) 30,000 CPH

Placement Accuracy 50 μm, 3 Sigma

Minimum LED Size 1 mm x 0.5 mm (0.039" x 0.019")

Maximum LED Size 20 mm x 18 mm (0.78" x 0.70")

Capability for Other SMDs Same maximum and minimum component size as LEDs

PICK UP SPECIFICATIONS

Tool Changer Yes

Number of Tools 18 (3 Per Head)

Accepts Additional Tool Changers Yes

Integral Vacuum Yes

BOARD HANDLING SPECIFICATIONS

Board Handling Method Magnetic fixture worktable (standard)

or inline conveyor (optional)

Maximum Board Length 23.6" (600 mm) standard

47.2" (1200 mm) optional

Full length assembled in a single pass

Maximum Board Width 12.6" (320 mm) 11.8" (300 mm)

with inline conveyor option

Board Thickness 0.008" to 0.12" (0.2 mm to 3.0 mm)

Fiducial Recognition/ Coordinate Correction Yes

Bad Mark Detection Yes

FEEDER CAPACITY

Maximum Number of Feeder Ports 16

Tape Feeder Sizes 8, 12, 16, and 24 mm

PROGRAMMING

Operating System Windows®

PC, Keyboard, Mouse Yes

Monitor Flat LCD

Teaching Camera Yes

Numeric Data Entry Yes

CAD Download Yes

Step and Repeat for Matrix Boards Yes

Optimization Functions Yes

Off-Line Programming Yes

MECHANICAL SPECIFICATIONS

X Axis Drive Mechanism High Speed Linear Drive

X Axis Encoding Linear

Y Axis Drive Mechanism Ball Screw

Y Axis Encoding Rotary

X-Y Axis Resolution 0.01 mm (0.00039")

Z Axis Resolution 0.01 mm (0.00039")

θ Axis Resolution 0.09°

θ Axis Range of Motion 360°

PHYSICAL SPECIFICATIONS

Overall Dimensions (Approx. L x W x H) 600 mm Length Board

48.4" x 44.4" x 58.7"

(1230 mm x 1130 mm x 1491 mm)

1200 mm Length Board

103.5" x 44.4" x 58.7"

(2630 mm x 1130 mm x 1491 mm)

Approx. Net Weight 450 kg (992 lbs.)

FACILITY REQUIREMENTS

Standard Voltage 200-230 VAC - Single Phase

Air Pressure 80 psi, 4 CFM, 5.5 Bar

SERVICE AND SUPPORT

Remote Diagnostics Ethernet

Warranty 1 Year