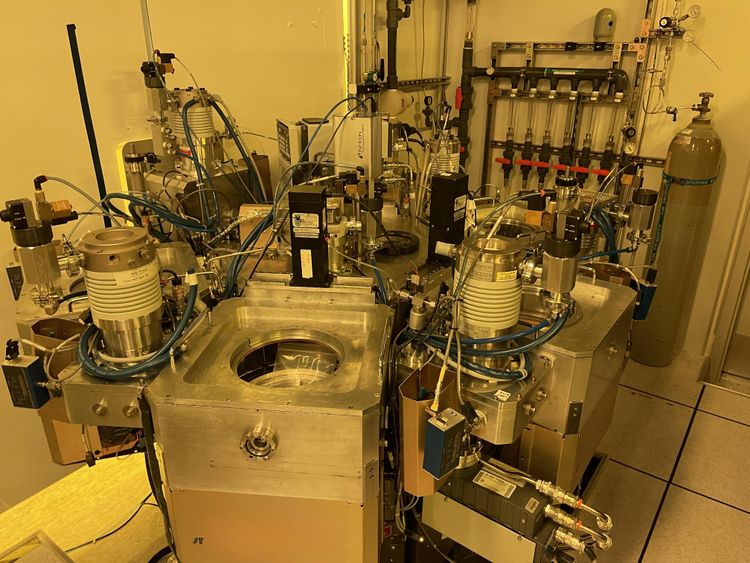

SFI Endeavor AT

AMERICA North (USA-Canada-Mexico)

PVD cluster tool

Version: 150 mm

Vintage: 01.06.1990

This tool was not operational prior to removal and

has missing parts.

De-installed by the OEM . In working condition. Warehoused. Can be inspected by appointment.

PM1 ETCH

PM2 Al

PM3 Cu

PM4 NiV

PM5 Ti

1. These tools have been upgraded to

the model Endeavour AT type from Endeavour 8600 type.

2. The difference between them is Endeavour 8600 has

RF Diode controlled sputtering,

whereas the newer Endeavour AT model has

RF S-Gun magnetron controlled sputtering,

along with optional Infrared substrate heaters.

3.The main design features of the system include:-

a. Sputter up deposition with gravity retaining.

No clips or clamps needed.

b. S-Gun magnetron advanced DC source.

4. You can run a receipe on the wafer with up to 50 steps with

different parameters for sputtering.

5. Each wafer loaded can be run through a different sequence of

sputtering.

6. The S-Gun magnetron sputtering system has

the following design features.

Plasma is produced in the chambers in 2 concentric rings.

One for each magnetron and target.

Between them, there is the shield region.

Sputtering happens if you have ions and

you have bombardments.

There is no plasma in the shield region, so ,

no sputtering of this section takes place.

At the edge areas of the targets,material is not sputtered.

Material is actually deposited there.

The sputtering volume is small due to the chamber design.

The magnets are designed so as the sputtering will

occur only over the centers of the areas where

the targets are located.

Magnet design is made in a way that the flux lines are

only above the target areas.

Electrons will then bounce between these 2 negative points of

the target and a plasma will be formed inside this region.

Hence, there are 5 sources of energy which can be applied to

the wafer. By adjusting the parameters of

these 5 energy sources,

you can adjust the grown film's characteristics e.g. grain size ,

film stress etc. etc.

7. Material analysis found no significant contamination in

the material of the sputtered films.

8. The optional substrate IR heater is a quartz lamp.

2 concentric lamps. They will heat wafer up to 500c within

1 minute.