Nsc schlumberger, Seydel, Zinser Acrylic yarn spinning

MIDDLE EAST

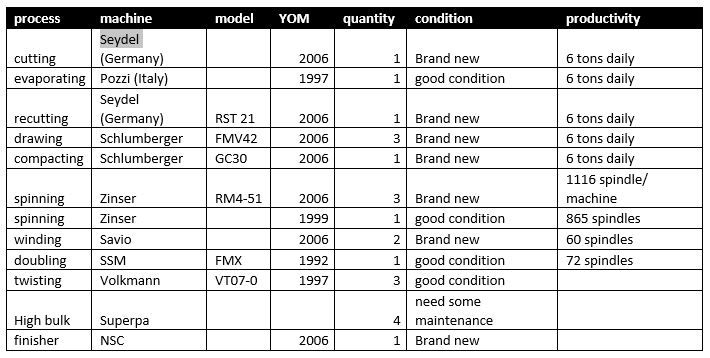

Preparations Department

• The first stage: Seydel cutting machine with a production capacity of 6 tons per day

• The second stage: Seydel re-cutting machine, production capacity of 6 tons per day

• The third stage: 3 NSC drawing machines, with a production capacity of 6 tons per day

• The fourth stage: 1 NSC Venture twisting machine, production capacity of 8 tons per day

• 2006 machine models in excellent condition, all of European origin

Secondly, the spinning department

• The fifth stage: 3 Zinser machines (each with 1116 spindles)

• One 864-spindle Zinser machine

• Spinning production capacity: 28 yarn/2hp 3000 kg per day or 5 tons of 14/1 yarn

Third, the recycling section

• The sixth stage: Two Savio Orion spinning machines, each machine having 60 mills, with a capacity of 7 tons per day.

• The seventh stage: One SSM spinning application machine with a capacity of 4 tons per day

• The eighth stage: 3 Volkmann thread weaving machines, with a capacity of 1800 kilograms per day.

• The ninth stage: 4 Superbuy steam processing machines with a capacity of 2,300 kilograms per day.

In addition to services

• Half ton steam boiler

• 2 Atlas air compressors

• Cooling Shiller

• Autoclave for preparing textile threads

• The factory has complete facilities (electricity, water, etc.)

• The machines are equipped with mixing polyester and viscose materials with acrylic to reduce the cost and improve the quality

3 machines each 1124 spindle

Yarrn14/1. 3 ton per Day

Yarn28/2 2 ton per Day

Yarn size 14 *28*40*50*80nm

long stable fibre