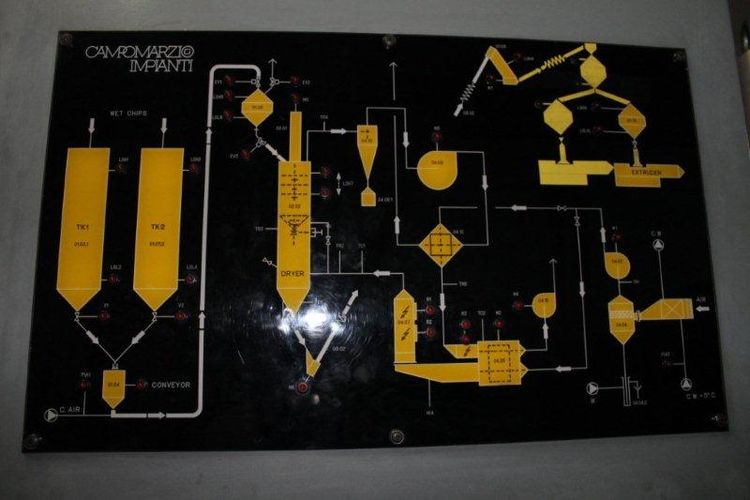

2 Others Extrusion complete line

EUROPE (Western and Northern)

Brand:

Process Air Room Model AEL Vent. 4.5KW Resistors 90KW Capacity 10000 Cubic Meters Hour

Process Air Wire Models AEL Vent. 15KW Resistances 45KW Capacity 16000 Cubic Meters Hour

6 FIO cooling cabinets.

1 Chiler Carrier GH60 Power 95KW Average working temperature 7ºC Year 1998

Water and reservoir pumps related to Chiler operation.

Cabinets cooling wire in the passage

6 Polymer pumps 2.4x6cc

7 Polymer Pump Reducer Motors

6 Pumps of oil ens picture 0.06x12cc

7 Oil Pumps Reduction Motors picture

2 oil deposits picture 100LTs

2 Deposits with Agitator to make oilimagi with capacity to make 200LTs at a time.

1 Dryer with (drying capacity of 200Kg per hour) 15KW motor and built-in electric cabinet resistors on the side.

3 Fan-related motors Drying: 1Vent. Input Air Motor 2.2KW Capacity 2300 Cubic Meters Hour;

1 Vent. Extraction Air Dryer Engine 18.5KW Capacity 2620 Cubic Meters Hour;

1 Vent. Extraction Air Regeneration Drying Engine 0.55KW Capacity 1150 Cubic Meters Hour.

1 Munters also related to Drying Engine 0.18KW

Complete electrical boards (Control all the automated process).

1 Extruder EOC90 Year 1989 Engine 55KW Resistors 32KW Average working temperature 285ºC Line C

with dosing capacity 130Kg per hour, 284DTEx 3140Kg Dia, 140DTEx 1548Kg Dia, 105DTEx 1161Kg Dia, 85DTEx 940Kg Dia, 60DTEx 663Kg Dia

1 Spare Screw for the EOC 90 Extruder.

1 Extruder EM60 FO Year 1997 Engine 45KW Resistances 26KW Average working temperature 285ºC Line D

with dosing capacity 65Kg per hour 284DTEx 1570Kg Dia, 140DTEx 774Kg Dia, 105DTEx 580Kg Dia, 85DTEx 470Kg Dia, 60DTEx 332Kg Dia

1 Spare Screw for the EM60 Extruder.

2 Transport motors PET Polymer with internal spring.

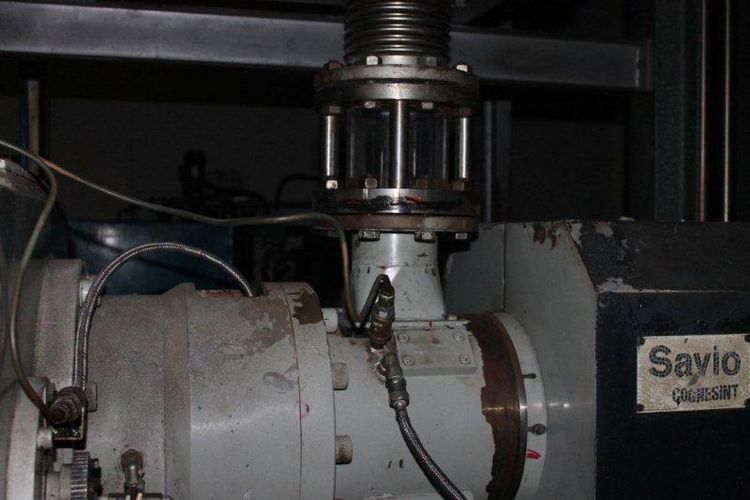

7 Cognesin winders average working speed 3200 meters per minute.

1 Pulce vein to transport the PET to the Internal Circuit with automated system.

1 Silo with capacity for 25000Kg of PET.

1 Equipment with built-in Compressor to transport polymer (to be shipped in 1000Kg bags or in Bulk Container) to supply Silos.

2 Built-in PET filter blocks with respective filters each row

2 Dosers line C: 1 = EnginPlast DG 15 dose from 0.300Gr to 10Kg 1 = from Ketron 0.500Gr to 10Kg

We can produce Color Yarn with Mate, Anti-flog, Anti-bacterial, Anti-UV, others ...

2 Dosers line D: 1 = from EnginPlast DG 15 dose from 0.300Gr to 10Kg 1 = from Ketron 0.500Gr to 10Kg

We can produce Color Yarn with Mate, Anti-flog, Anti-bacterial, Anti-UV, others ...

1 Dye drying oven Year 1997 National with the capacity to dry +/- 50 kg each time.

1 Dyeing stove Year 1994 with capacity to dry +/- 30 kg each time.

Filters 10 Filaments

Threads

Threads 36 Filaments

Filters 48 Filaments

Tapes 68 Filaments

Filters 72 Filaments

Tapes 96 Filaments

Threads 36 Hollow

Multilobal spindles

Octolobal Tapes

Tire triangular

Trilobal Tapes

Crosss Section Tapes

1 Boiler LinhaC ORLANDI Maximum values of work 2.5Bar / 350ºC; Average working values 0.

7Bar / 283ºC Power 66KW; Dimensional Liquid Capacitance 850LTs

1 Boiler LinhaD ORLANDI Maximum values of work 2.5Bar / 320ºC; Average working values 0.

7Bar / 283ºC Power 36KW; Capacity 620LTs

1 PET firing furnace: nozzles, pumps, static mixers and others.

1 Apparatus for washing glass microspheres to wash materials: Blocks and others.

1 Ultrasound for washing nozzles and others at +/- 80 ° C.

1 Microscope to inspect nozzles.

1 Press for mounting press on rails in the die assembly.

Electrical control panels related to control pumps Polymer oil pumps picture and Extrusion

4 internal PET supply tanks: 1 = 400Kg PET; 1 = 560Kg PET; 1 = 260 kg and 1 = 50 kg

1 Furnace Year 1989 Heating nozzles; Polymer and other pumps

1 Furnace National Year 1994 Heating nozzles; Polymer and other pumps