Wolf

United States (USA)

Reference #43222

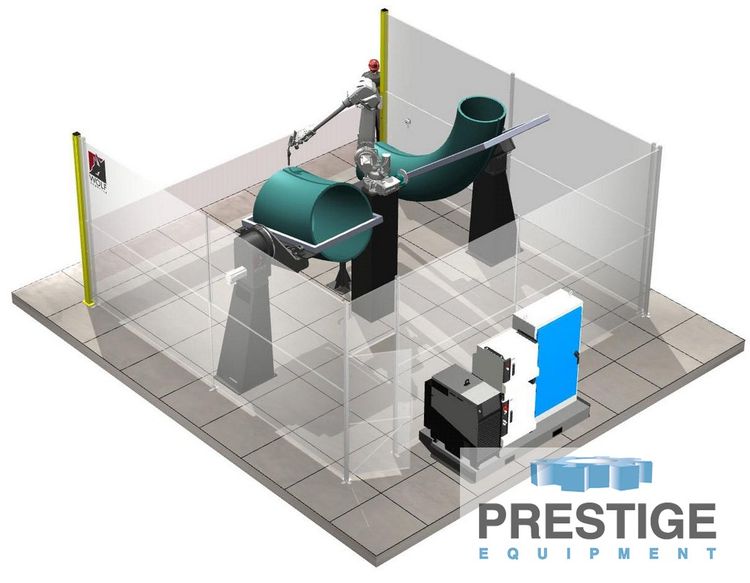

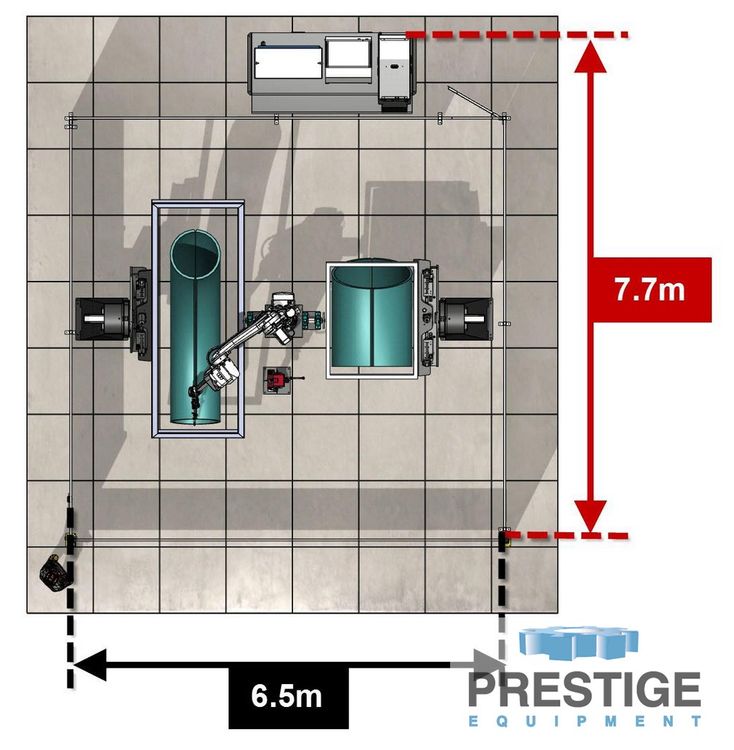

Wolf Robotics Welding Cell

FEATURES:

IRB 4600-40 2.55 Six Axis Robot Packag

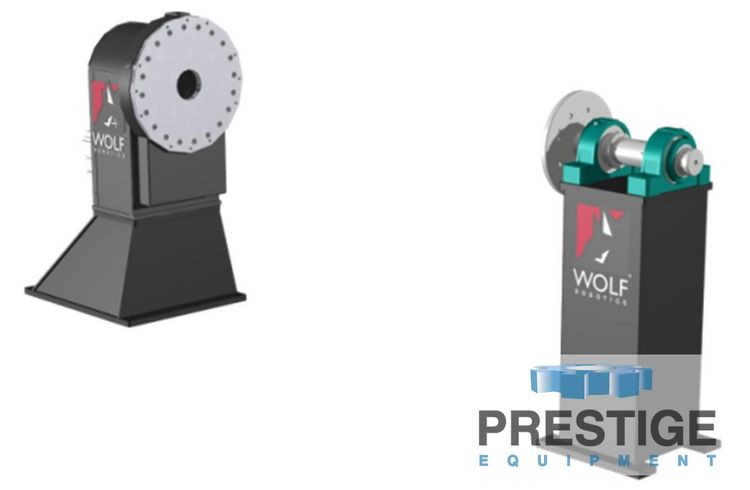

HeadStock/TailStock 6,000KG Servo Positioning System (QTY 2)

Laser Spot Finding Package

Lincoln Power Wave SAW Package

BullsEye TCP Calibration System

Touch Sense

Operator Panel

Main Cell Interface Panel Without Power Distribution

Safety Package

WolfWare™ Software Package

Production Manager

Pneumatic SmartDock™ for Fixtures

Specifications:

IRB 4600-40 2.55 Six Axis Robot Package:

IRB 4600 6 Axis Robot

IRC5 Controller

Collision Detection

Path Recovery

Multitasking

Color Touch Screen FlexPendant (10m Cable)

Cable Management

Specifications:

Reach: 2550 mm

Repeatability: 0.06 mm

Payload Capacity: 40 kg

No- te4:8 F0oVr 3lePahd time, this is a gently used floor robot from Wolf

Robotics. Full Warranty still applies. (Color: Orange)

HeadStock/TailStock 6,000KG Servo Positioning System (QTY 2):

Single axis AC servo positionerPillow block style Tailstock

Full coordinated motion between robot and positioner axis

Specifications:

6,000 kg. load capacity including fixture

Max load up to 4,016 NM torque

Laser Spot Finding Package:

Fast, non-contact searching

Compact and rugged design

Search 1 dimension returning a vector offset

Combine searches for multi-dimension offset

Awliltohw Ws ofolfr Hceaalcvuyl aWtiveeld aindga pptaivcek awgeeld ing of large joints when combined

Search for part present functionality

Advanced Replay for WolfArcTM:

True shape replication for multi-pass welding

Eliminates defects due to path interpolation

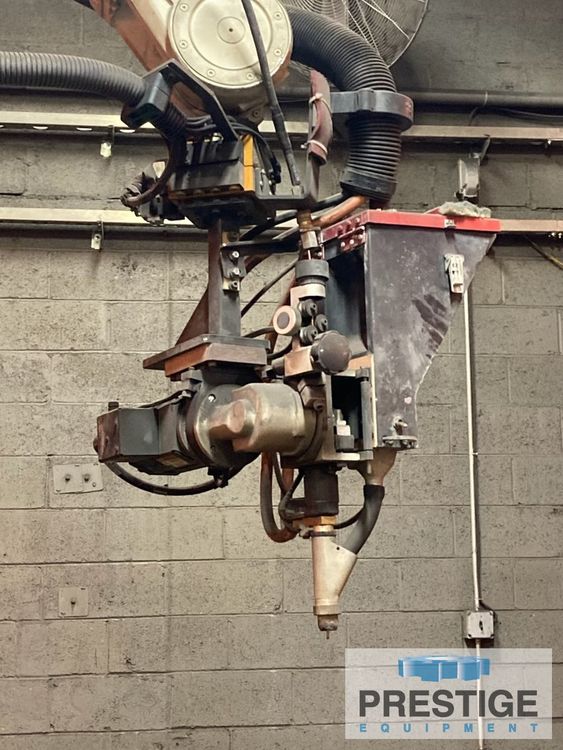

Lincoln Power Wave SAW Package:

Includes:

Power Wave AC/DC 1000 SD

MAXsa 19 Controller

MAXsa 29 Feed Head

Iennveerrgtey rd-beamsaendd d esign reduces

True Energy Capable

Touch sense enabled

Process stop package

Robot Dress out package

Flux Recovery System:

W30e0l dU Enniteg ineering PFR-3000-

MM-1500X Vacuum Unit

Flux Nozzle

Without Heated Flux

BullsEye TCP Calibration System:

Automated calibration of Tool Center Point (TCP) based robot tools

including (but not limited to):

MIG welding torch

Oxy-fuel cutting torch

Automatically adjust tool position and angle to ensure path repeatability

Supports up to five unique tools per robot

Integrated error handling

Optimized update times

Includes calibration check pointer for quick visual reference

Touch Sense:

Tactile interface

Ability to search with weld wire or gas cup

Search 1 dimension returning a vector offset

Combine searches for multi-dimension offset

Search for part present functionality

Operator Panel:

Twist Release E-Stop

Programmable Manual Jog (If Applicable)

OK to Enter Pilot Light

Safety Reset / Op Ready

Program Start

Program Stop

Main Cell Interface Panel Without Power Distribution:

Hoffman enclosure – NEMA class 12

Back plane assembly

Mounting for Seam Tracking, Tactile searching interface, safety, etc

Cable covers as required.

Jokab Safety PLC

Safety Package

Safety PLC

Stack light status display

Modular safety fence

Light curtains with pre-reset / op-ready push buttons - M aintenance gate with safety switch and gate-reset push button

WolfWare™ Software Package:

Advanced calibration procedures for offline to online programming

Cell move instructions with support for axes masking

Torch cleaner supporting instructions for arc-welding applications

Automatic pre-part and post-part execution routines

Base functions to support process specific software packages

Production Manager:

Real time production information on each task the robot is executing

Teach Pendant Graphical Interface supporting:

Customizing setup and service routines

Execution of setup and service routines

Execution of user-created part routines

Managing part routines

Part/program handling functions with both name and pictures

Process interaction through easy to understand graphic symbols

Minimum amount of operator training required

Note:

Any and all Software and License is the buyer's responsibility to Confirm