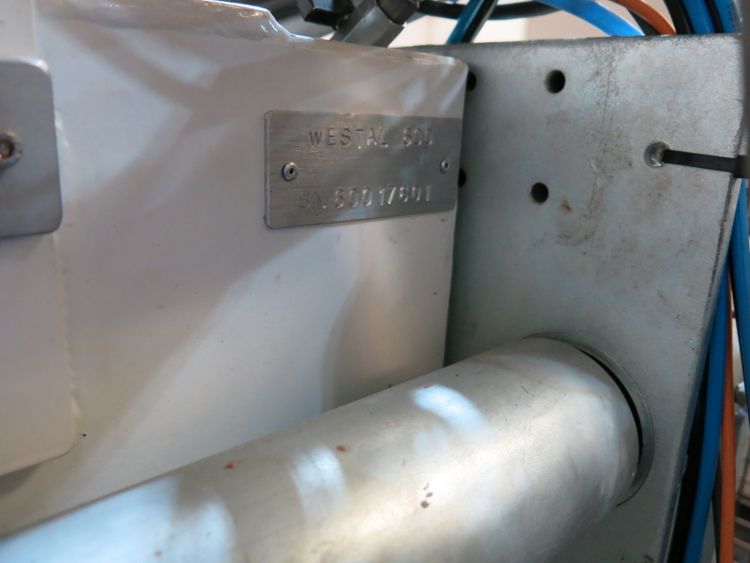

Westal 600 One Shot Chocolate Moulding Line

EUROPE (Western and Northern)

ONE SHOT CHOCOLATE MOULDING LINE

Manufactured by WESTAL

Type 600 One Shot Chocolate Moulding Line,

Currently set up for book moulding & producing 7grammes solid chocolate eggs. Can also produce bars, shell moulded products, one shot products, etc.

Line was new in around year 1980, had a complete overhaul in year 2009. This overhaul was done by the present owners, using extra contract engineers.

For the Overhaul, this included:

Pulling down the line to every last bolt and checked all bearings, etc. and replaced any which were not 100%. Rebuilt all worn shafts cams, etc. and wire brushed or soda blasted all metal parts that were not painted and reassembled. This was very extensive. Also totally reconditioned the depositor end including the mould closer and repainted /plated most parts. All electrical field wiring was replaced and any control gear not deemed to be reliable. All the insulated panel doors and enclosure were replaced with new panels, hinges and latches. Moulding Line includes electrical wiring diagrams.

Additional work done later is as follows:

2011 - Replaced the mould closer pneumatic logic controls with a plc controller and new valves which proved a lot more reliable.

Also put a plc control on the demoulding hammers.

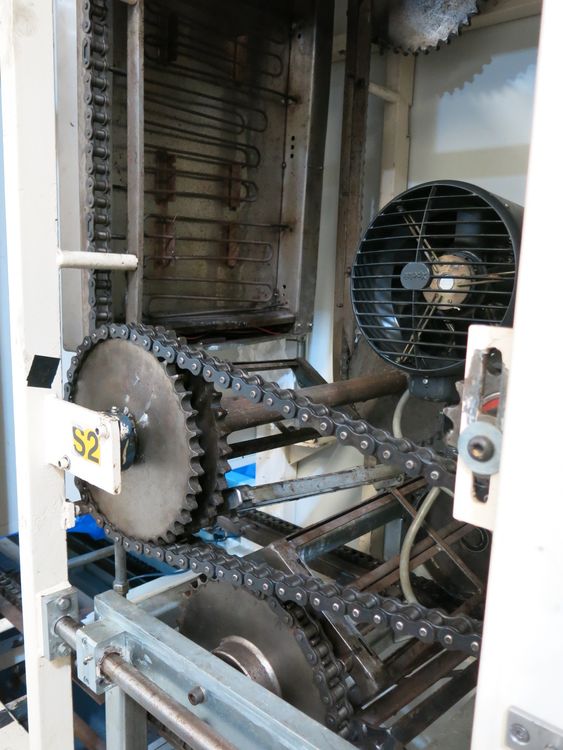

2012 - Installed a more powerful air circulation fan motor and variable speed control on this.

The line measures 26 metres long plus an extra 4.5m for the outfeed conveyor, egg sieve, GORING KERR DSP1 Metal Detector (which runs on the following test pieces: 1.5mm ferrous, 1.5mm non ferrous, 2.0mm stainless) and Elevating Conveyor.

Mould size plain: 600mm x 220mm.

Book mould carrier 600mm x 220 mm. The two half egg moulds that go in these are 505mm x 100mm.

The moulding line has capacity for 600 moulds but only includes around 400 book mould carriers.

The line consists of :

Mould Heat Station, One Shot Depositor, Mould Vibrator for open moulds, Mould Closing Station, Mould Vibrator for closed moulds, Cooling Tunnel (serpentine), Mould Opening Station, and Pneumatic Mould Tappers. The moulds then return inside the top or the tunnel to the mould heat station.

Line was producing about 230-250 Kg/hour on 7gramme eggs in either compound or chocolate.

Also includes a full set of 13gramme egg moulds moulds and depositor plate to match.

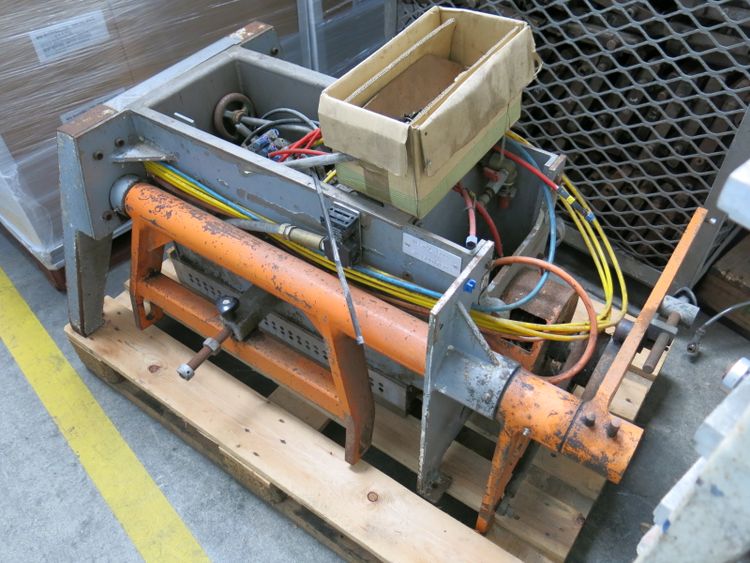

Also with this line are numerous other moulds and depositor plates, and two extra Depositors (one is a one shot and the other is one sided) which are currently in storage. The one shot one has larger pistons than the one currently fitted to the line, and includes a depositor plate and some moulds for this for doing a 30gramme filled egg.

The moulding plant has its own evaporator on the roof of the building but does not have its own condensing unit as it is run off the factory compressor rack.

Set up in the factory, currently not in production.