RDM MicroBlend Beverage Processing System

AMERICA North (USA-Canada-Mexico)

MicroBlend Beverage Processing System, Year 2004

– Manufacturer: Bevcorp/RDM Technologies Micro Blend Model: MicroBlend

– Software: Windows based software up to date

– Year: 2004

– Last Running: 500cpm @ 16oz (3800 Gallons/hr) – Set up for Ammonia

MicroBlend reduces oxygen and nitrogen levels in the blended product. Product can now be achieved with low parts-per-billion levels of O2 and N2. Deaeration occurs without the use of water deaeration. Reduced processing hardware; vacuum pumps, vessels and membranes no longer needed. Reduced blender cost, operating cost, and a simpler process. Less volatile product at the filler; improves operating speed and temperature requirements. Deaeration occurs in CIP loop; improves Micro issues. This system includes a Maselli Brix Analyzer upgrade.

· Carbonated soft drink blenders offer optional CO2 or N2 injection with water deaeration and product chilling

· Hot fill and non-carbonated blenders are manufactured without the gas injection, deaeration, and product chilling

· Multi-stream blenders enable the addition of multiple streams of flavors and ingredients to the finished product

· Approximate Overall Dimensions:

Water Deaeration Skid 96” L x 96” W x 120” H

Blending Carbonating 144” L x 96” W x 130” H

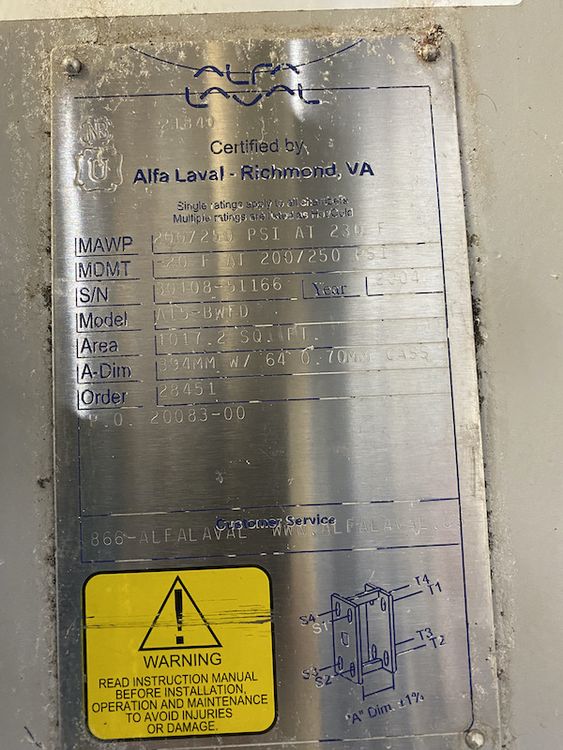

Plate & Frame Chiller 144” L x 36” W x 120” H