Parpas Diamond

United States (USA)

Reference #43516

Parpas Diamond 5 Axis Linear Gantry Type Vertical Machining Center

FEATURES:

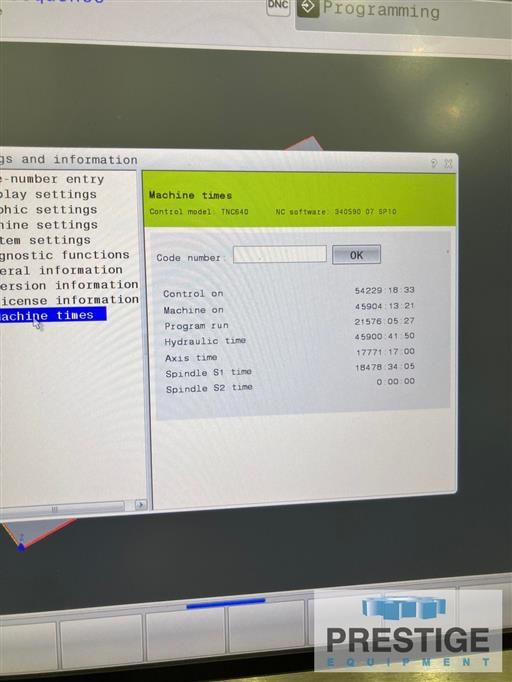

Heidenhain TNC 640i

24-Station Automatic Tool Changer

Coolant around the spindle 450 PSI

Air around the spindle 100 PSI

Radio touch probe M&H

Tool laser pre-setter Blum

Chiller Unit

Linear Drives & Motors

HVAC Controlled Gantry, Parpas Patent

5-Axis Dual Torque Motor Driven Liquid Cooled Head

Parpas Patented Long-Life High Speed Spindle Model MTS-29.92

with HSK-63-A Tool Holder. 20,000 RPM

SPECIFICATIONS:

Longitudinal Travel X-Axis ............ 87"

Head Travel, Y Axis ................... 59"

Ram Travel, Z axis .................... 39"

Spindle Nose to Table, Vertical ....... 48.6"

T-Slotted Table Dimension ............. 91" x 63"

Clearance Between The Columns ......... 106"

5-Axis Head Pivot Value ............... 12.99"

X and Y Axes Feed Rates ............... 3149" IPM

Z Axis Feed Rate ...................... 3149" IPM

Linear Motors ......................... All 3 Axis

Machine Footprint ..................... 204" x 156" x 192"

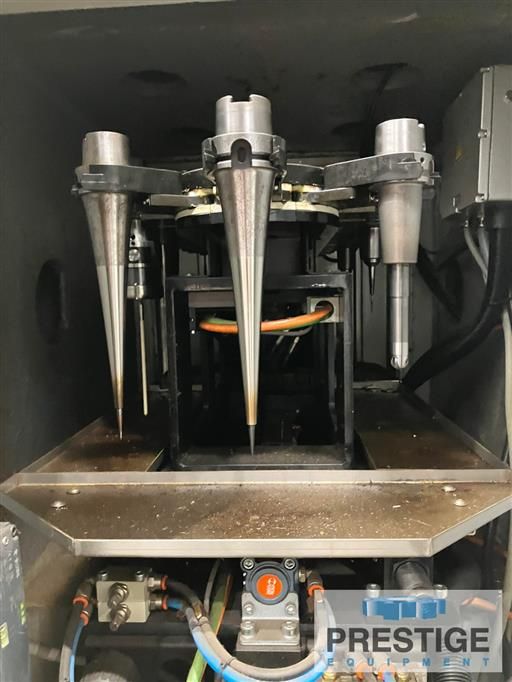

5-Axis Milling Head:

Continuous Indexing Head

A & C Axis ............................ (TOE-29 Head)

Ram C-Axis Range ...................... +/- 370°

Head A-Axis Range ..................... +/- 105°

A & C Axis Head Positioning Increment . 0.001° Each Axis

Spindle Speed ......................... 20,000 RPM

Power (continuous) .................... 29 kW

Constant power range .................. 3,000 -20,000 RPM

Spindle torque ........................ 92Nm S1, 117Nm S6

Spindle taper ......................... HSK-63-A

EQUIPPED WITH:

Heidenhain TNC-i640 CNC Control

24-Station Automatic Tool Changer

Coolant around the spindle 450 PSI

Air around the spindle 100 PSI

Radio touch probe M&H

Tool laser pre-setter Blum

Chiller Unit

Linear Drives & Motors

HVAC Controlled Gantry, Parpas Patent

5-Axis Dual Torque Motor Driven Liquid Cooled Head

Parpas Patented Long-Life High Speed Spindle Model MTS-29.92

with HSK-63-A Tool Holder. 20,000 RPM

Remote Hand Held Pendent with Electronic Hand-wheel included.

19” Large Format Hi-Res Monitor

Stainless Steel and LED Lighting inside the Working Cabin.

BLUM Tool Laser Pre-setter System and with Tool Family Software.

Digital Measuring Touch Probe

Flood Coolant System External to the Spindle

Through-Tool High Pressure Coolant 735-PSI

Paper Tray Coolant Filtration System (Losma)

Water Gun for chips (wash down)

Oil Skimmer

Air/Coolant Tool Cooling with Switching (through the spindle and around)

Dual Front & Back of Table Chip Conveyor System

Tele-service

Kinematic option without calibration sphere

Machine 3D model (for the simulator)

(2) Chip Conveyors

Note:

Additional 12.99" or 6.49" Per Side can be reached on the X & Y Axis

by rotating C-Axis with Head in the Vertical Position.

Hours:

Approx. 17,000 Cutting Hours