Allimand Two-Wire Paper Machine for Testliner and Fluting 2.900 mm 80 to 240 gsm 200 TPD

EUROPE (Western and Northern)

Complete production mill incl boiler and effluent system

Output capacity of 75,000 tonnes per year and produced brown recycled corrugated case material, primarily testliner.

GSM Range: 80 to 240.

Speed: 600 m/min (balanced for 700 m/min, drive 1000 m/min).

Stock preparation for 200 TPD.

Complete stock preparation plant supplied mainly by Black Clawson and Lamort Kadant. 1994 – 2000.

Main components:

Pulper, 4 – 5 % consistency with a 260 KW motor, with an inclined conveyor, junk box; also equipped with a grapple to grab out large impurities;

Hydrapurge detrashing system;

Selectpurge Dewatering Drum;

Screw conveyor system for rejects;

Belt conveyor for sludge;

Compactor;

Three stage coarse screening with pressure screens;

Further fine screening system;

Vibrating screen;

Cellusizer Fractionator and two lines fibre distribution (long and short);

Liquid Cyclone System;

Gravity inclined screen;

HD Cleaners;

Refiner, deflaker;

Three batteries of LD cleaners;

Pumps, pipes, flow meters, agitators etc.

Water tank (SS) for pulper water;

Reel guillotine;

Paper machine deckle: 2950 mm on reel-up. 2850 mm after the winder.

Bottom wire: cantilevered with Bellmer headbox, year 2022.

Steam box.

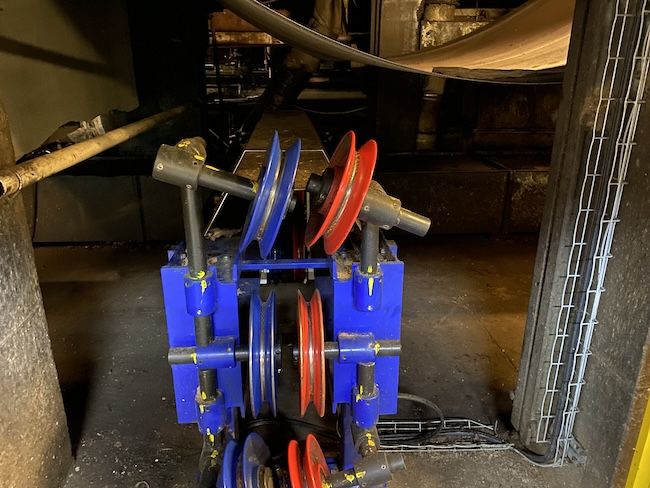

JUD fabric tensioning system, 2021.

Top wire with Allimand octopus system headbox, year 1998.

Suction roll.

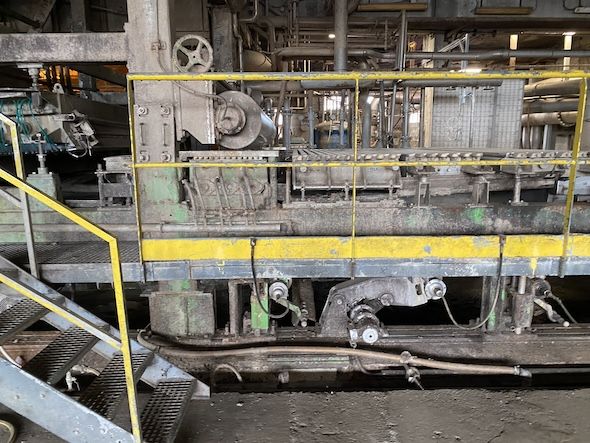

Gorostidi Press Section with three presses, 1995.

48 Drying Cylinders Allimand, 1957, 2 bar pressure.

Rope threading system, 2022.

Pope reeler ABK Allimand, 2001.

NASH Vacuum Pumps System.

The paper machine has a sectional silent ABB ACS MultiDrive, 2021 – 2022.

Andritz tail threading system.

Fibre recovery rectangular unit.

QCS System: Honeywell Davinci HC900.

Jagenberg Vari-Dur Machine Winder.

Machine hall cranes, 12000 kg capacity.

Paper Roll Handling system with a 3500 kg capacity roll clamp and floor conveyor.

Boiler house with two Babcock Wanson boilers, 10 bar each.

3 Renault Generators, 1.2 kW each.

Effluent plant with a fibre recovery system.

Spare parts, including all machine rolls, machine clothing, other spares.

Complete set of technical documents and drawings.

video available

2900-mm-PM-Flowsheet pdf available (see in photos)

- note OFFER will not be shared with professional used machine dealers/ resellers.