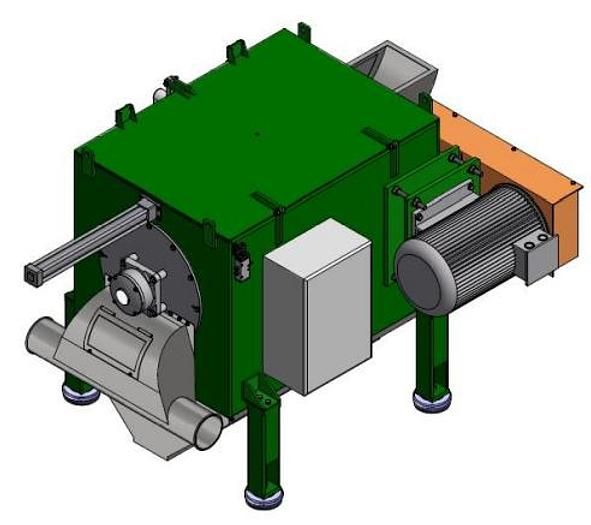

Others DRYING CENTRIFUGE 200-400 Kg/h rigid plastics 15kw (or 11 kw)

EUROPE (Western and Northern)

DRYING CENTRIFUGE

sturdy construction in carbon steel on the outer structure and AISI304 stainless steel for all the parts in contact with water : loading hopper, paddle rotor, separation baskets, water discharge hopper, material discharge hopper, Pneumatic displacement cleaning kit

Manual jack opening system

Anti-vibration feet

Electric panel can be supplied separately, if needed.

Rotor diameter 300 mm

Rotor length 800 mm

Rotation speed 2.900 rpm

Basket holes 3 mm

for reground PE PP PC PS ABS.

grinding size: Ø12÷20mm, of variable thickness

Production capacity 200÷400 kg/h, depending on material and water content

Installed power kW 15 kw, (available with 11 kw drive)

The CF series centrifuges allow optimal separation of water and residues from the product to be processed.

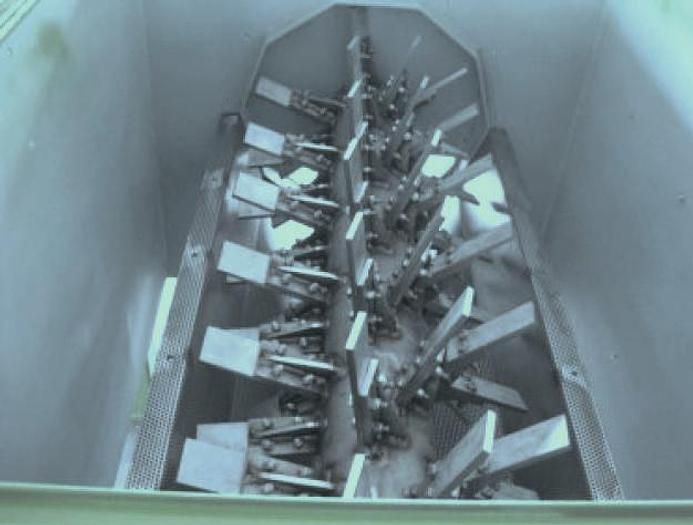

The material fed into the machine is projected against the perforated walls of the separator by a rotor. The latter, thanks to the particular inclination of the blades, simultaneously advances the material towards the extraction section.

The external structure of the machine is made entirely of carbon steel and the supports are equipped with anti-vibration anti-vibration supports.

The perfectly balanced rotor is made of hardened and stabilised steel and is supported by a roller bearing system. roller bearings.

The separation basket, consisting of two half-shells, is made of stainless steel.

The motorisation is of the electric type with belt transmission.

The machine is also equipped with a special inspection cover and can be completed with a system of cleaning of the internal baskets with pneumatically driven brushes.