cutting the polyurethane foam waste for a polyurethane recycling processes

EUROPE (Central and Eastern)

cutting the polyurethane foam waste for a polyurethane recycling processes.

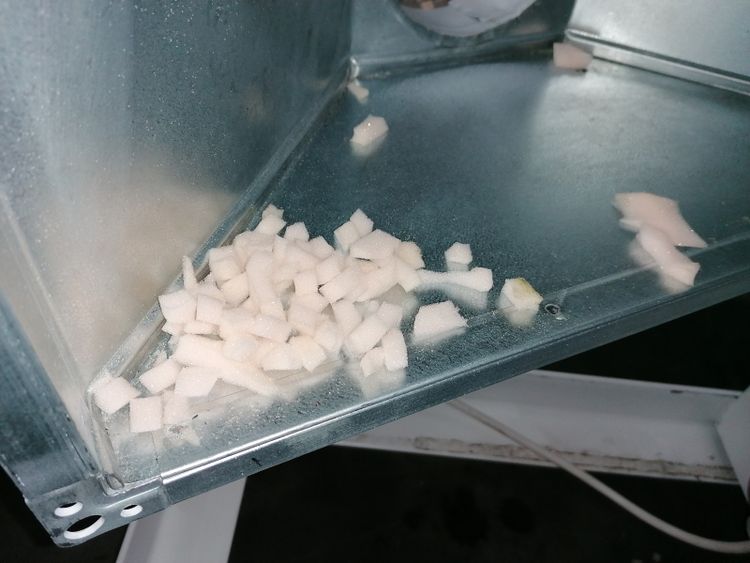

The product which you receive is perfect for a production of fulfilling pillows, and furniture industry. Small size and high efficiency would be great for a fabrics which are producing furnitures and has a waste of foam.

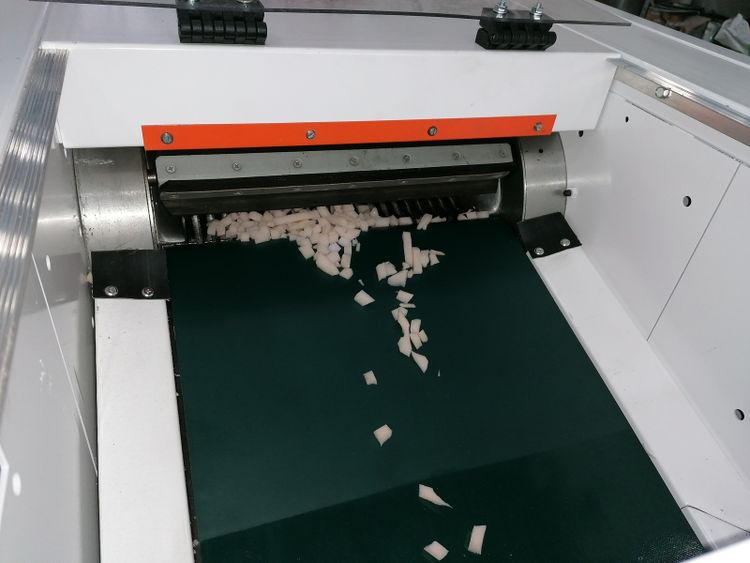

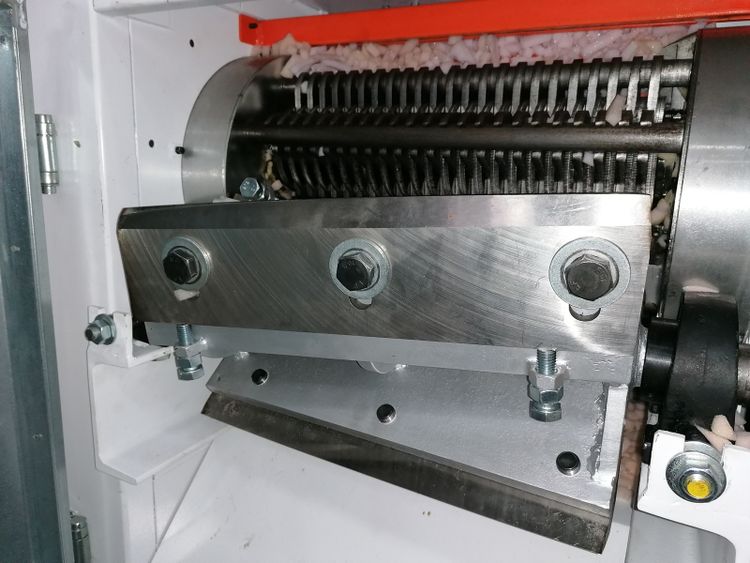

The machine consists of three cutting units, which are cutting polyurethane foam. The raw material is fed to the feed conveyor belt, which takes the raw material to the loading tunnel. In the loading tunnel, the foam is fed to the first cutting section.

On the first cutting section, the raw material is cut into flakes and then directed to the chute by a conveyor. The cutted foam is implicated by the second cutting section where the piece is cutted in the second plane.

From the second cutting section, the cutted foam is transported by the lower and upper conveyor to the third cutting section, where the piece is cutted in third plane.

The cutted polyurethane foam is sucked out by the packing station - the bag which places the product in bags.

Specification

Efficiency: do 300 kg/h

Working width: 500 mm

High: 1150 mm

Lenght: 2500 mm

Mass: 290 kg

Power: 10 kW