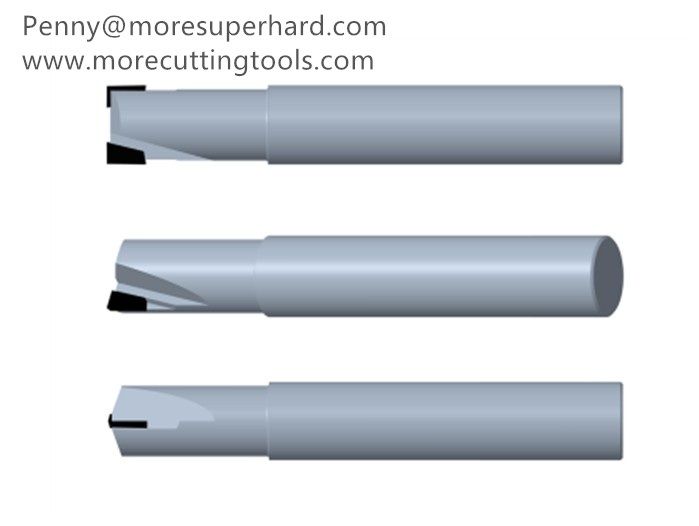

Other PCD end mill, cbn end milling, mill for gearbox bottom

China

Performance advantages of PCD/PCBN milling cutters

●With ultra-high hardness and super wear resistance;

●Stable performance and long tool life;

●High processing efficiency and low cost;

●High surface finish can be obtained;

●High conductivity, good toughness.

●Forming slot milling cutters have been successfully used in slot milling.

●Multiple slots can be formed and milled at one time, which reduces the use of tools and the number of tool changes, and greatly improves the processing efficiency.

●The water outlet design in the tool center can effectively reduce the processing heat in the cutting area, reduce tool wear and make the tool have a longer processing life.

PCD universal milling cutter, suitable for processing aluminum and aluminum alloys, copper and copper alloys and other non-ferrous metals, glass fiber and metal composite materials, glass, engineering ceramics, engineering plastics, and milling of materials such as stone and wood.

Suitable for high-efficiency Plunge milling, side milling, slot milling, contour milling, and spiral interpolation milling.

PCD/PCBN milling cutters features

▲The cutting edge adopts laser technology, the cutting edge is sharp, and the cutting is light and suitable for high-speed occasions.

▲ PCD of medium grain size has both abrasion resistance and chipping resistance, and excellent overall performance.

▲Diameters of the same specification, different cutting edge lengths.

▲The cutting edge over-center design can be used for axial feed milling similar to drilling.

▲Optimize the groove shape to achieve a higher dynamic balance level.

▲The small R angle and chamfering of the cutting edge effectively increase the durability of the tool.