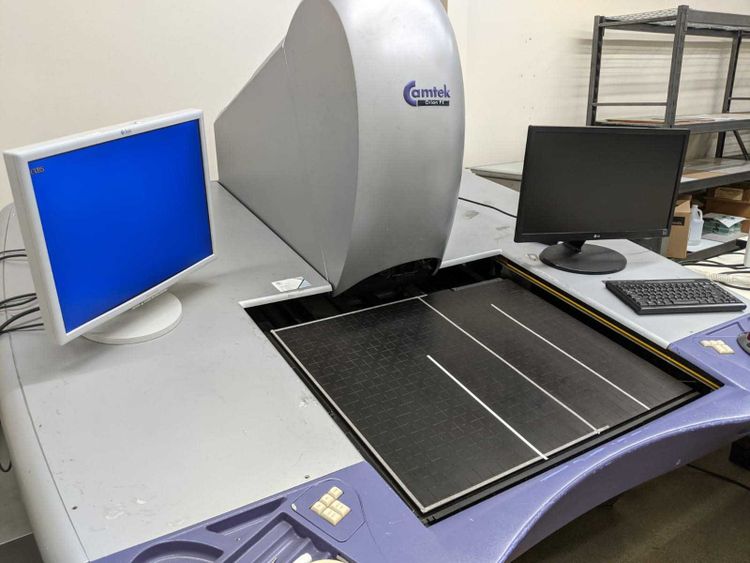

Orion AOI Camtek Orion 868 for pcb production

RUSSIA and Central Asia

Used equipment, produced in 2011. The unit is in excellent technical condition, fully operational and ready for use.

PCB Technology Down: to 30 µm line/space

Throughput: Up to 190 sides/hour (application dependent) based on 24”x18” (610mm x 457mm) panel size

Panel Size (Maximum): 30”x24”(762mm x 610mm)

Panel Thickness Range: 1 – 200mil ( 0.025mm – 5mm )

Panel Types and Designs: Inner and out layers; build-up and sequential lamination layer including Signal, Analog, P&G,

Mixed, Cross-Shield, Laser drilled layer and other

Material Inspected: All copper foil types; Copper plating; Photo-Resist(optional); Gold plating ; Teflon and

Ceramics(optional) Silver-Halide and Diazo, Alternative Oxide-Durabond

Detectable Defect Types: Open and Short-circuit, Nick, Mouse-bite, Protrusion, Pinhole, Island, Dish-down, Line/Space

width violations, Annular ring violations, Extra and Missing features

Reference Source Data: CAM

Tooling: Pin-less

Operation System: Window XP™

Verification & Repair Methods: Inspectify™; Offline verification station

Dimensions Orion 868

Height 68.5”(174cm)

Width 71.7”(182cm)

Length 68.1”(173cm)

Weight 850kg

Power 100/240 VAC; 50/60Hz; 2.5Kw

Compressed Air: 6ATM, 1L/min

Temperature and Humidity: 22±3℃; 50±10%RH

Optional Features

CRPT/CRG: Offline reference station

Low Contrast Materials: DSTF, Double Treated and other low contrast materials

Laser Drill Inspection: Allows inspection of conformal mask and laser drill applications

PRI-Photo Resist Inspection: Allows inspection of Photo-Resist