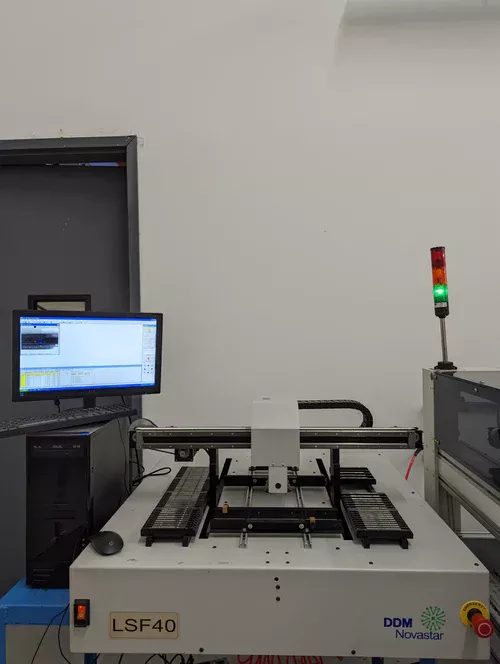

DDM, Novastar LSF40 Prototype Pick and place machine

AMERICA North (USA-Canada-Mexico)

Comes as shown in photos with PIK strip feeders

Features

• Provides the most economical solution in a fully automated pick and place bench- top system

• Capable of placing a wide range of components from 0402 discretes

and SOICs to PLCCs and 20 mil pitch QFPs

• Placement rates up to 1800 cph

• Friendly, easy to use Windows® based software

• Tape strips can be set up easily using the unique PIK-StripTM feeders

• 8, 12, 16, 24, 32 & 44 mm PIK-StripTM feeders available

• Capable of handling cut tape, stick/tube and loose components

Specifications

Max board area L-SF40 . . . . . . . . . . . . . . .13.5” x 22” (343 x 560 mm)

Max travel area L-SF40 . . . . 22”(X axis) x 22”(Y axis) (560 x 560 mm)

Z axis max travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5” (38 mm)

Board thickness . . . . . . . . . . . . . . . . .0.020”- 0.156” (0.5mm - 4.0 mm)

Typical verifiable placement rate . . . . . . . . . . . . . . . . . . 1200-1800 cph

Placement accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.004”

Fine pitch capability . . . . . . . . . . . . . . . . down to 20 mil pitch (0.508mm)

Smallest component capability. . . . . . . . . . . . 0402 packages standard

Largest component size . . . . . . . . . . . . . . 1.378” (35mm) square body

L-SF40 max no of lanes. . . . . . . . . . . . . . . . . . . . . . . . . . .72 - 8mm tapes

PIK-StripTM available . . . . . . . . . . . . . . . . . . . . . . . . . 8, 12, 16, 24 mm

Tube feeders (bulk also) . . . . . . . . . . . . . . . . . . 8, 10, 14, 18, 24, 32 mm

Matrix tray feeders . . . . . . . . . . . . . . . . . .with Board/Matrix tray holders

Component orientation Ø-axis motion . . . . . . . . . . ± 360° in 0.18° step

System dimensions L-SF-40 . . . 36” x 38” x 25”h (914 x 965 x 635 mm)

On-the-fly component centering . . . . . . . . . . . . . . . . . Centering fingers