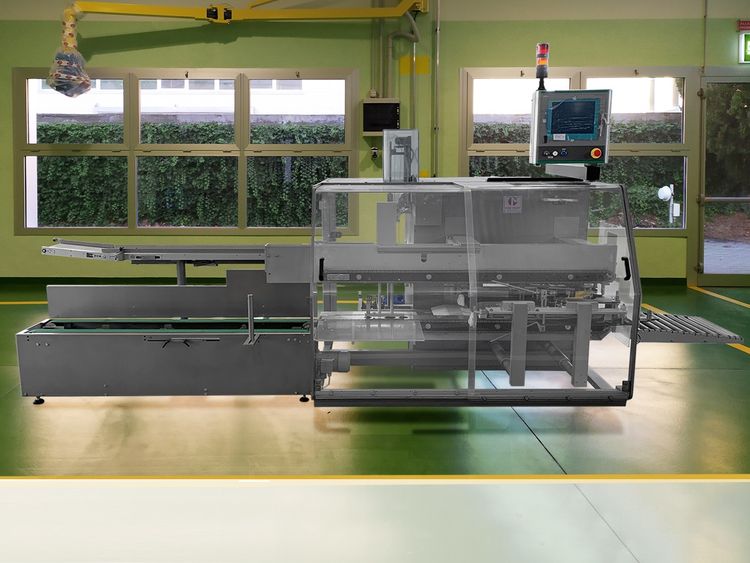

MARCHESINI MC 820, Automatic case-packer

EUROPE (Western and Northern)

Main Features

Balcony design to improve accessibility, maintenance and cleaning operations;

Machine composed of three working sections: cartons collation, case feeding and closing;

Working area and case transport, separated from the mechanics placed on the rear;

Case changeover adjustments in “B” (width) and “H” (height) quotes, are made through servo motors with direct command from the operator panel;

“A” quote (length) automatically managed when setting of the format parameters is made from the PC.

Cartons Collation

Collation of cartons, coming from the upstream machine, on the infeed conveyor belt;

Pick & Place for the direct transfer of the cartons into the hopper, with vertical stacking from the bottom to the top;

Product pick up detected at each cycle of the collation, to assure that the defined number of products has been collated;

Machine stop in case of wrong pick up;

Product transfer into the case, at the end of the collation phase, by the mechanical command of pusher and hopper.

Cases Feeding

Case feeding on a 1750 mm (68.897”) long conveyor belt, placed at 450 mm (17.716”) from the floor, accepting many stacks of flat cases all over its length and one stack in the pick-up area;

Suction cups arm for the picking of the flat case from the top of the stack and case transfer into the forming and loading station; case forming and keeping in the opened position during the introduction of product;

Possibility to process a wide range of cardboard boxes sizes without the use of change parts;

Automatic adjustment of the strokes of the picking arm and case transport chains, without neither manual settings nor size parts.

Cases Closing

Flaps folding and subsequent case closing with adhesive tape.

Safeties and Controls

Safeties guards in methacrylate, integrated in the machine frame;

Emergency circuits and protections with safety level;

Overload control on the machine brushless motorizations;

Torque control on product loading hopper and pusher;

Minimum load control, with machine under idle status in case of lack of cartons at the infeed;

Maximum load control on the infeed conveyor with stop of the upstream machine upon receipt of a signal detecting maximum load of product;

Minimum load control of the cases inside the magazine with acoustic pre-warning signal and machine stop;

Control for the unsuccessful case opening with machine stop;

Control for the adhesive tape breaking with machine stop and acoustic signal in case of tape reel end.