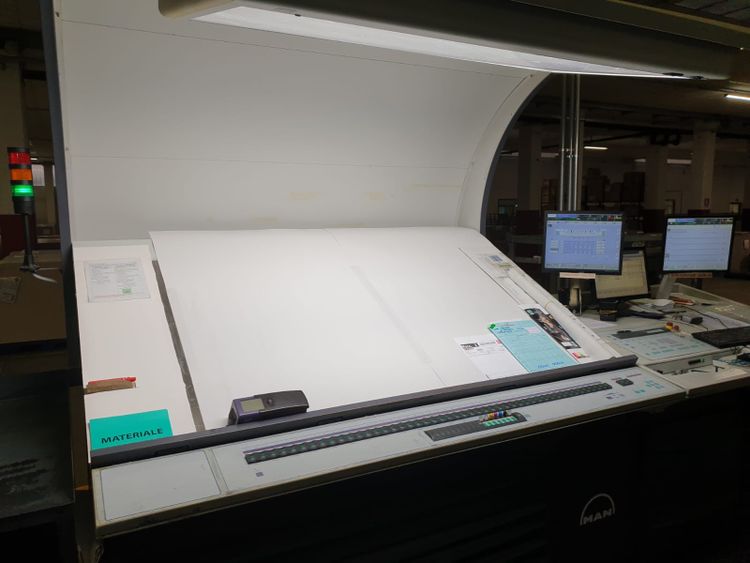

MAN Roland R 906-6 LV

EUROPE (Western and Northern)

RCI ink control system

Circumferential, lateral and diagonal register remote control

Roland-Deltamatic damping unit

Automatic Ink wash-up device

Automatic blanket wash-up device

PPL Semi-automatic plate change

RCI console for ink and axial, circumferential for plate cylinders

InLine Color Pilot (Graphometronic) : spectrophotometer and register control (after 5th unit; installed on 2015 about)

Pneumatic side lays

Pile alignment on feeder

Non-stop on feeder with swords

Semi-automatic plate change (PPL)

Roland-Deltamatic System damping

Technotrans ink temp control combined with damping refrigeration + Automix

Technotrans beta.f cabin : dampening solution fine filtration

Automatic roller wash-up device

Automatic blanket cylinder wash-up devices with brush

Automatic impression cylinder wash-up devices with brush

TRANSFERTER: Ventury Air Transfer system

Preset automatic sizes adjustment on feeder and delivery, on pressure, on gripper bars transfer cylinder

Ink ductor temperature control

Automatic impression cylinder wash-up with brush on coating unit

Machine Elevated 375 mm

Varnishing unit, with cooking register, Tresu chambered doctor blade system, with anilox roller

Dryer Eltosch IRx8 lamps (4 slides), HOT air knives dryers

Grafix Cantronic 3000 powder spray

Extended delivery

Non-Stop in delivery

PIAB Vacuum & Blow System remote controlled

13.000 speed/h