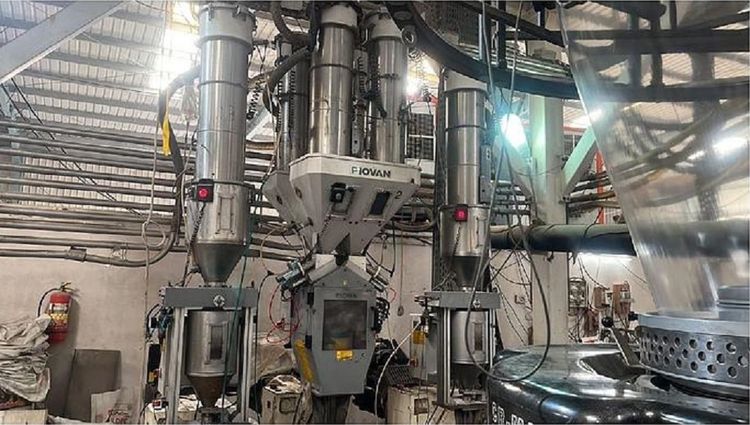

Macchi Blown Film Extrusion Line

United Kingdom

Number of layers: 5

Film structure: ABCDE

Material: Nylon and Evoh base barrier film

Film width: 2200

Output: 480kg/h

Extruder 1 layer: A

Screw diameter 1: 65mm

Description 1: Gravimetric dosing units, 4 comp, groove feed, bimetal barrel, barrier

Screw melt pressure sensor before screen change

Extruder 2 layer: B

Screw diameter 2: 45mm

Description 2: Gravimetric dosing units, 1 comp, groove feed, bimetal barrel, barrier

Screw melt pressure sensor before screen change

Extruder 3 layer: C

Screw diameter 3: 55mm

Description 3: Gravimetric dosing units, 4 comp, groove feed, bimetal barrel, barrier

Screw melt pressure sensor before screen change

Extruder 4 layer: D

Screw diameter 4: 45mm

Description 4: Gravimetric dosing units, 1 comp, groove feed, bimetal barrel, barrier

Screw melt pressure sensor before screen change

Extruder 5 layer: E

Screw diameter 5: 65mm

Description 5: Gravimetric dosing units, 4 comp, groove feed, bimetal barrel, barrier

Screw melt pressure sensor before screen change

Die diameter: 450mm, 5 layer die head, 10 zones heating, 550 x 2mm insert

for LLDPEIBC with 1 air chiller bubble control, automatic inner bubble exchange

by high speed stepper motored valve, air ring with 64 heating inserts

Bubble cage: 1100-2100mm lay flat motorized calibration cage, ultrasonic web break detector

Take off unit: horizontal oscillating take up, AC vector drive

Corona treatment: 2 side

Web guide

Rewind: double back to back

Rewind maximum reel diameter: 1200

Rewind: 2 station contact winder, 40-250N web tension, antistatic system, 4 core air shafts

Air chiller exchangers for OBC & IBC

Edge trim slitting and blower

PLC control

Touch screen control 15”

Maximum: 150m/min