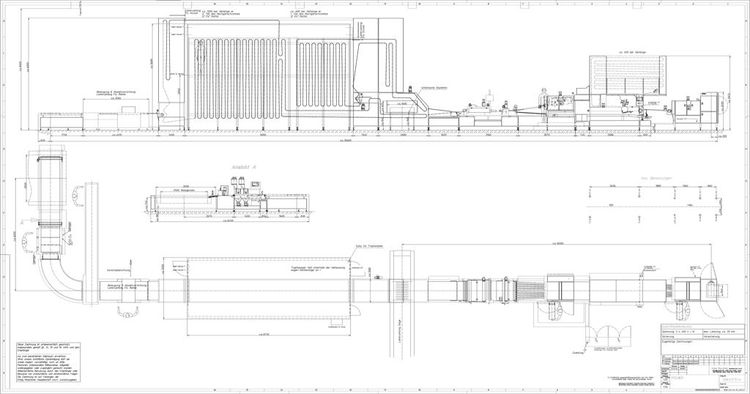

König KGV Combi 2000 line

EUROPE (Western and Northern)

IV. SPECIFICATION:

Item 10

1 Rex Automat Type Industry II T 8/6/5 S-I; Model 2000

Weight range approx. 30 – 130 g depending on the dough

Roller feed hopper with star shutdown and oiling

Shutdown of 2 and 3 rows (8/6/5 row operation)

with duster via feed belt to the sander

three additional sanding drums

Spreading belt with a nominal length of 1600 mm, can be lowered for direct passage DD under the pre-proofing cabinet system

Chain belt duster

Stauber over spreader tape

Automatic controls with servo motors for setting the machine via the Siemens Blue Line control panel (TP 170)

Stainless steel panels

Spreading belt with stepper drive

Chain belt with filler bars

3 x 400V / 50Hz

Item 20

1 pre-proofing cabinet system KGV IV (900/450)-K8-K8(J)-SA8(J)-VO-DD regrinding device-WDK-RR1000

Approx. 450 assignable plastic hangers with welded-in troughs, 8 rows, crosswise division 110 mm

Pre-fermentation time approx. 14.4 minutes at a set 31.25 strokes/min (15,000 pieces/h)

Air conditioning with heating, electric, and humidification, with saturated steam provided by the customer, controlled by a thermostat and hygrostat

automated fresh air supply

Disinfection system and drying zone with fan for empty hangers

Direct transfer option (DD) under the pre-proofing cabinet via the lowerable spreader belt of the Rex Automat Type Industry

Double setting roller for row correction and intermediate belt leading to the ball spreader belt

REGINAMATIK stamping station with pre-dust, own pressure cups and turret stamping head with the stamping tools:

* K8 (fixed) – Kaiser rolls 8 rows

* K8(J) (fixed) – Kaiser rolls 8 rows in jour weight

* SA8 (on support plate) – round pressed salt rolls (rosettes),

8 rows in Jourweight; If necessary, more can be found here

Stamping tools can be used on the carrier plate.

* VO (permanently mounted) – pusher for round unstamped rolls, 8 rows

Reginamatik transfer belt for final position adjustment, height adjustable

Continuous discharge belt leading to the end of the pre-proofing cabinet, followed by an expanding belt to set the necessary transverse divisions

Stainless steel panels

Regrinding device after pre-proofing cabinet system for Wachau production

further hanging tipping output from the pre-proofing cabinet

with feed belt to the drum sander and mounted duster

Drum sander from the model 2000 series - 8 rows, second action

an additional sanding drum for party pastries

Spread band output

Delivery via double deposit roller on line

Forming station WDK-RR1000

Working width 1000 mm

Double roller calibration head with duster for upper roller

Wrapping shoes with 6 and 5 rows for discharging products from the wrapping gap

Lower belt, speed adjustable

driven upper belt, direction of rotation reversible, speed adjustable

Timing roller at the end of the lower belt with transfer roller (removable) for row correction

Lowerable intermediate belt leading to the secondary proofer

Stainless steel panels

3 x 400V / 50Hz

1 distracting unit ABe1000/2500

Working width 1000 mm

Pulling length 2500 m

for loading the oven loader

with pneumatically lowerable nose for deep transfer of the dough pieces

The exact design is coordinated by our design office with the oven supplier

Stainless steel panels, Stainless steel feet, Stainless steel plates

Overall system

· controlled via Siemens Simatic S7 with Siemens “Blue Line” touch panel

· with stainless steel panels, stainless steel screw feet and stainless steel base plates

· 3 x 400 V / 50 Hz