Ima 1800-23-B COMPLETE POWDER FILLING LINE

EUROPE (Western and Northern)

The sterile powder filling line was produced in 2023, and tested and has been packed, but never been used.

The Equipment is stocked already in crates, it is not possible to see the machines.

Model: 1800-23-B / 1250-FLS / RT120 / XTREMA PWD-L / ALU400 / HYDRA480 / V-600

consisting of

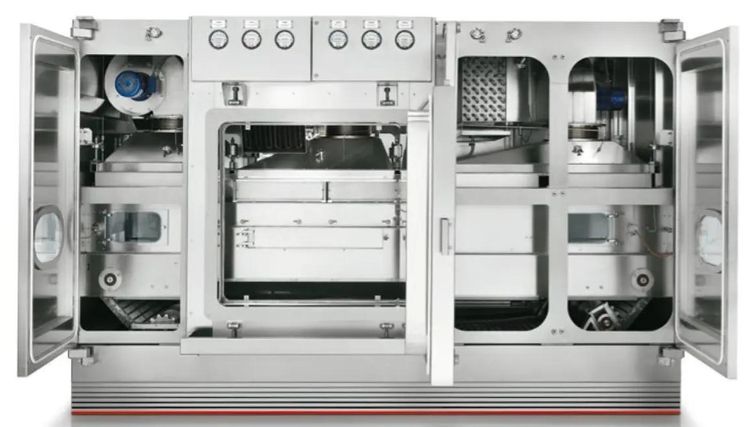

1) HYDRA LINEAR CONTAINER WASHING MACHINE, MODEL 1800-23-B

Linear washing machine, suitable for washing glass and/or plastic containers used in the pharmaceutical industry, guarantees the removal of particulate contamination of at least 3 log. (particles such as glass, fibres, oxides, etc.). Designed and built in accordance with cGMP.

Capacity: Up to 27,600 containers / hour

RANGE OF CONTAINER SIZES: Min. diam.: 16 mm x max.: 36 mm x max.: 110 mm

• Min. mouth diam.: 7 mm

2) DEHYDRATION / STERILISATION TUNNEL BLUE GALAXY, MODEL 1250/FLS with continuous dry heat for glass containers.

The tunnel consists of three main areas:

a) entry area with vertical air flow;

b) 2 heating areas with vertical air flow;

c) 2 vertical air flow cooling zones.

DIMENSIONS: Length: 7025 mm x Width: 2410 mm x Height: 3175 mm Weight: 9000 Kg

3) RT 120 ROTARY TABLE WITH TUNNEL VALLEY

Rotating accumulation, sorting or loading table suitable for handling stable cylindrical containers, in glass or plastic, coupled with packaging lines.

RANGE OF STANDARD CONTAINER SIZES: Min/max diameter: 16-80 mm. Min/max height: 35-220 mm.

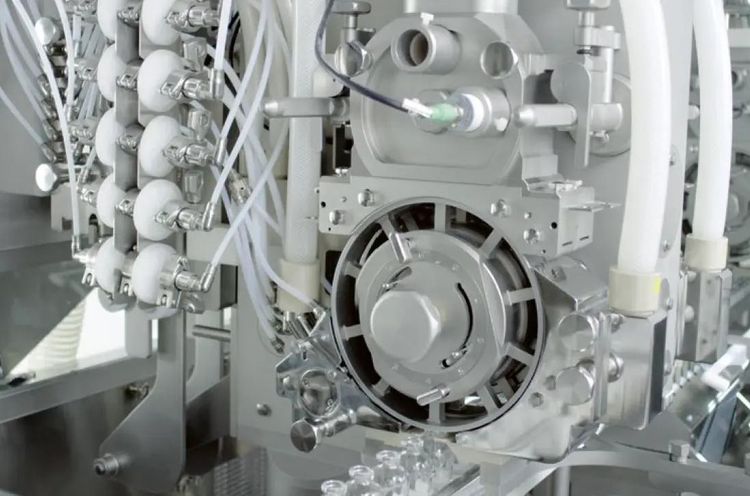

4) XTREMA PWD MICRODOSING MACHINE

Machine for filling and capping bottles at a maximum speed of 400 bottles/min. Suitable for volumetric dosing of powders, using vacuum-pressure technology, and for applying rubber caps.

Transport of 4 bottles at a time: Diameter: from 22 to 36 mm, Height: from 30 to 58 mm

Transport of 2 bottles at a time: Diameter: from 37 to 56 mm, Height: from 58 to 136 mm

5) ALU 400 RINGER for applying and edging aluminium rings, with or without a flip-off, on capped cylindrical glass or plastic containers.

SIZES OF CONTAINERS PROCESSED: Diameter: 14 - 52 mm, Height: 35 - 110 mm, Rings: max. diameter 40 mm

• Performance: up to 400 bottles/min.

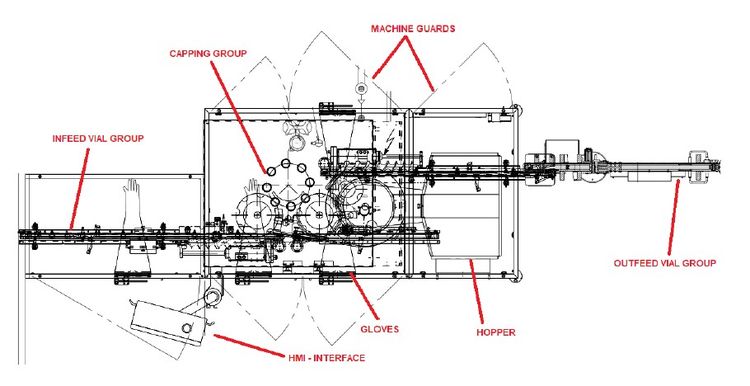

6) BOTTLE WASHING MACHINE HYDRA 480 for cylindrical or shaped glass or plastic containers. Includes parts for washing full-size vials.

MECHANICAL SPEED

• up to max. 480 vials/min. with a maximum vial diameter of 36 mm

• up to max. 200 vials/min. with a maximum vial diameter of 37 - 54mm

RANGE OF VIAL DIMENSIONS: Min/max diam.: 14/36 mm, Min/max height: 34/110 mm

7) 2-STATION SEED TRAY V/600 for plastic or metal bottles from an upstream machine. The machine has two stations and can process 2 trays per station.

SPEED: Up to 400pcs/l

• 20 strokes per minute

STANDARD BOTTLE DIMENSIONS: Min/max diam.: 14/52mm, min/max height: 33/110mm

TRAY DIMENSIONS: standard up to 310x500mm