Icbt BCF Fiber Extrusion Line

AMERICA North (USA-Canada-Mexico)

IFT BCF Fiber Extrusion Line, tri-color

2002 year.

One step spin draw texture system

Consisting of:

(3) Colortronic 2 component blenders with loader and panel.

(3) DAVIS STANDARD Extruders DS-15H, 1.5" x 30:1 L/D.

Spin Manifold.

(3) pumps and drive systems.

Quench system

Finish application system, 12 outlet with metered heads.

Draw Texturing Panel for 12 threadlines, consisting of:

Preheat godets.

Heated draw godets, 180mm x 270mm long, 185 deg C, 4000 mpm.

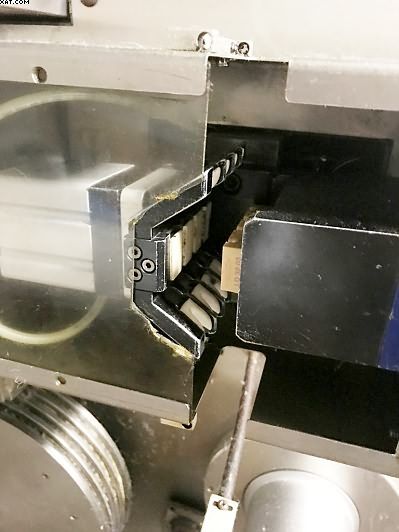

Four end split texturing jets.

Cooling drum assembly.

Take-off roll with separator.

String up aspirator.

(2) Barmag ASW 602 spindle driven turret winders, 2500 mpm, 73mm ID, 2x 250mm packages. Includes (1) spare winder used for parts.

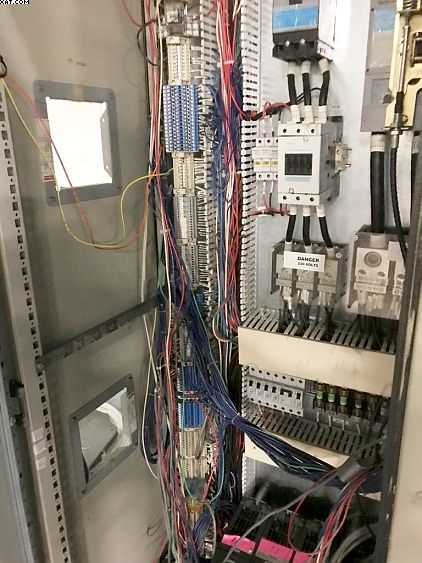

IFT and Quad Plus Electrical Control panels for heat control and drive systems.

STEELMAN Pre-Heat Oven, Model 222EBHT650, 12kw, 480v, 8 cu ft, 20x24x23", 650 deg.

STEELMAN Burn-Off Oven, Model 333BA-P and BA-C, natural gas, 270000 btu/hr, 120v, 40x40x40".

Last running recycled nylon 6. Reported capacity ~130 pph on 1200 denier and ~200 pph on 1900.

Includes manuals, drawings, & spare parts.

NOTE: The right side mezzanine holding the oven is NOT included.