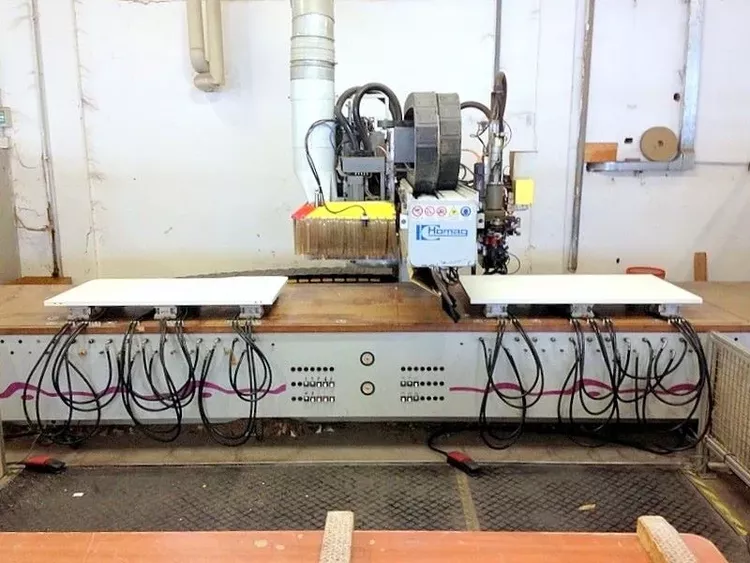

Homag Omptimat BAZ 32

EUROPE (Western and Northern)

CONTROL SYSTEM :

• NC Homatic, system NC 81 based on PLC

• Nr. 4 control axis (x,y,z,c) – Rotation 360°

• Moving speed max:

– 80 m/min X-Y axes

– 30 m/min Z axis

TECHNICAL DETAILS :

• Piece length:

– max 3.700 mm for single processing

– max 1.250 mm for alternated processing

• Piece width max 1.200 mm

• Piece thickness:

– with edgebanding max 40 mm

– without edgebanding max 60 mm

FLAT WORKING TABLE with rollaway backstop and possibility of installation of locking depression devices for pieces

• Nr. 8 Frontal stops (4 + 4)

• Nr. 4 Back stops (2 + 2)

• Nr. 4 Side stops (2 + 2)

• Nr. 12 Locking suction cups dual action

• Nr. 2 Vacuum pumps 100 m3

GLUING UNIT 360°/SINGLE EDGE :

• Edge height max 45 mm

• Plastic edge thickness min – max 0,4-3 mm

• Edge length min 230 mm

• Nr. 1 Magazine for edges with nr. 3 positions

BORING UNITS:

• Nr. 1 Horizontal boring unit with 4 spindles

• Nr. 1 Vertical boring unit with indipendent spindles

OPERATING UNITS – Rotation from 0 to 360°

• Nr. 1 Electrospindle 7,5 kW – HSK F63

• Milling tools diameter max 150 mm

• Nr. 1 End trimming saw blade unit 180 x 30 x 3,2 Z = 54

• Nr. 1 Rough trimming unit

TOOL CHANGER MAGAZINE WITH NR. 12 POSITIONS – HSK F63

• Circular magazine with 12 positions for tools/groups

ELECTRICAL EQUIPMENT :

• Separate electrical cabinet

• Operating voltage 380/400 Volt 50/60 Hz

NORM AND OPTIONAL FOR SECURITY

• CE Marks

• Frontal Electronic security mats