Heidelberg, Komori Offset line

EUROPE (Western and Northern)

Selling whole package: Heidelberg pre-press software (including servers, PCs etc)

+ Heidelberg CTP + Komori press with colormanagement.

The machine has ISO certificate (valid thru 08/2021).

Whole set is in operation and can be tested

Was used for express printing

Please note the whole set is in operation and can be tested. It was used for express printing. So we kept most of the capacity empty – it is basically new. All machines were whole time under Heidelberg/Komori official service care. On press are new (2019) rubber rollers.

Individual components of system:

1. Sheet-fed offset printing press KOMORI LITHRONE 420

4-colours, sheet-fed offset printing press for printing substrates up to format B3.

The machine has double circumference back pressure and dampening rollers.

The gripper system for feeding sheets through the machine has pads with industrial diamond.

Specification of machine - standard equipment

- Control and checking

- Remote control desk with touch screen at print delivery

Remote control of fountains, duct rollers and registers

Remote control of diagonal registers on dampening rollers

Remote control of fine setting of side guides (+-3mm)

- CIP3/4 compatibility

- Automation of print preparation

- KPC automatic plate loading

- System for rapid pre-inking and de-inking of KPD blanket

- Automatic washing of blankets

- Automatic washing of offset rollers

- Feeder

- Functional surfaces of sheet grippers with industrial diamond

- air ionization in feeder

- Vacuum conveyor in feeder

- Mechanical broadsheet control

- Ultrasonic double sheet sensor

- Optical misfeed sensors

- machine stop when misfeed on front guide

- Dials for setting front and side guides

- Blanket

- Ductors with separate servo drive

- Axial shift of distribution rollers

- Copper dampening and distribution rollers

- Possibility of setting axial shift of plate inker (2 inkers for machine)

- Dampening

- Komorimatic dampening

- Possibility of alcohol-free dampening without modification of machine

- Dampening rollers with axial shift

- Printer unit

- Double circumference back pressure and dampening rollers

- Functional surfaces of sheet grippers with industrial diamond

- chrome-plated forme cylinders

- chrome-plated offset cylinders

- chrome-plated back pressure rollers

- Dial for setting sheet thickness on control side of machine

- Control elements on both sides of printing unit on all units

- Delivery

- Counter and sheet stacker with pre-selection

- Sheet straightener

- Antistatic bar

- Plant sets, equipment

- Feeding and cooling equipment Technotrans Alpha.d 20L-4 Combicontrol 2.5, aquados.a 5

- Orion air pump for feeder

- Toho powder sprayer

- SBA isolating transformer (30kVA)

- BEIL plate punch (including installation rails)

- 3.5” disk drive for receipt and backup of data for blanket configuration

- Setting timing (interval) of blanket ductors

Counter as of 1.2.2021 - 35.6 million imps.

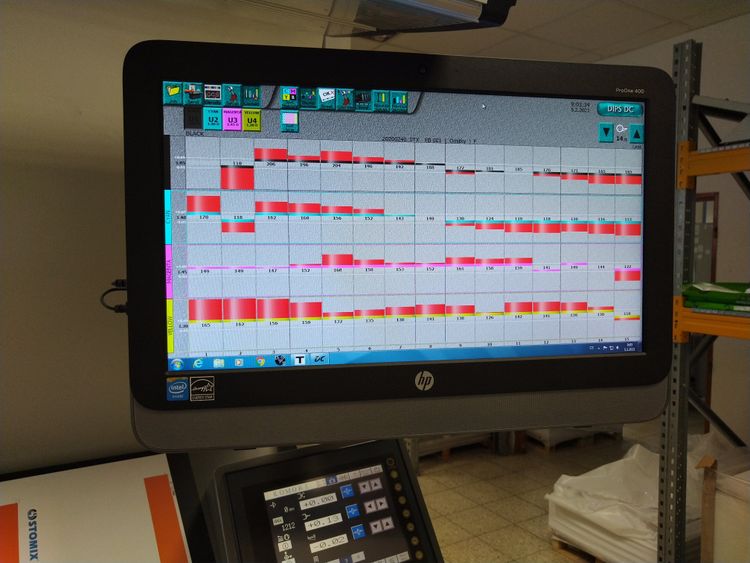

The machine also has a PC with densitometric measuring of print control scale with automatic control of blanket on the basis of software evaluation

- Scanning densitometer Techkon RS 4OO including AS 52 guide rails

- PC

- Online connection to Komori L42O control desk

- Display and “closed-loop” software - Color Control Software

- Presetting of blankets of machine Komori L42O - CIP3 line where prepress supplies tiff data for automatic setting and inking of blankets

Basic technical data

Maximum sheet format: 375 x 520 mm

Minimum sheet format: 100 x 148 mm

Maximum printing area: 340 x 510 mm

Sheet thickness range: 0.04– 0.6 mm

Plate dimensions: 400 x 530 mm

Feeder pile height: 800 mm

Delivery pile height: 500 mm

Maximum printing speed: 13,000 sheets/hour

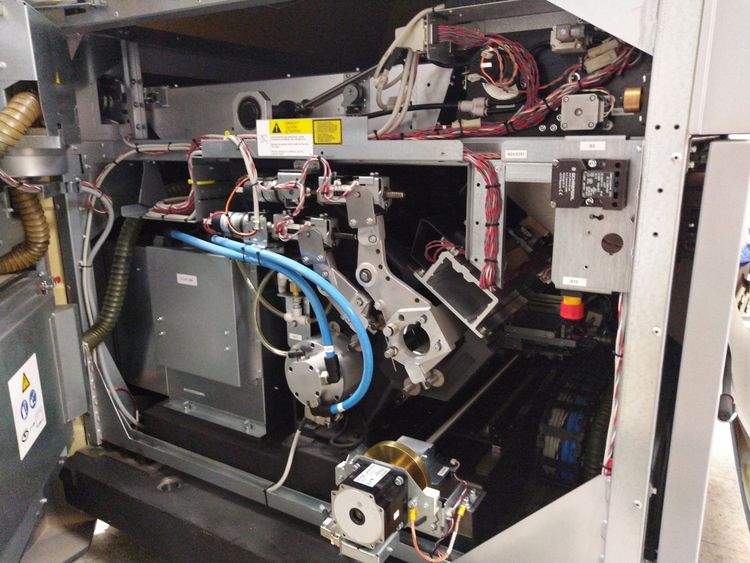

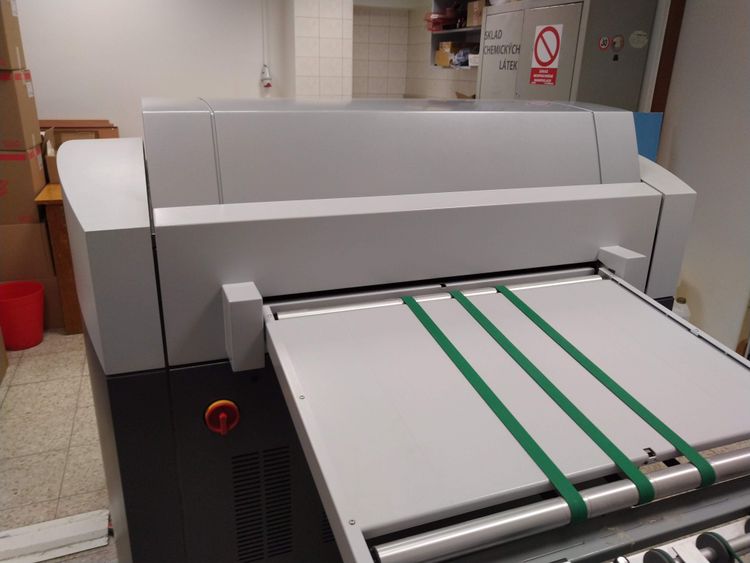

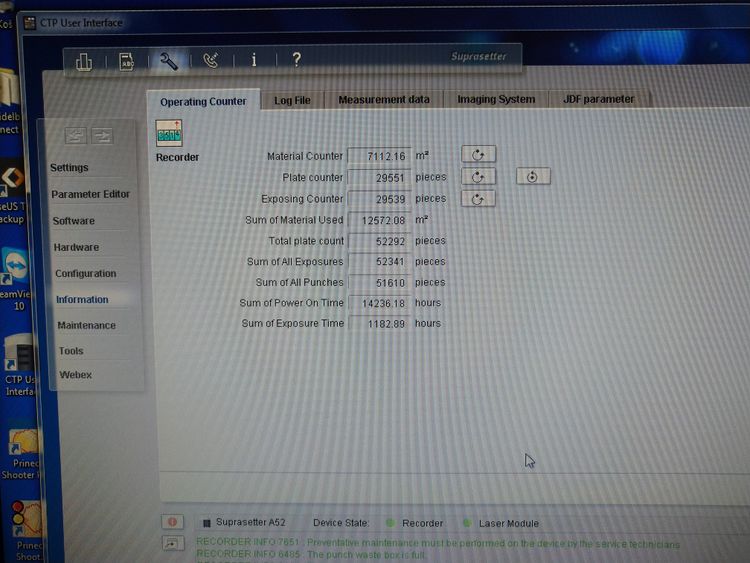

2. Thermal CtP platesetter

Heidelberg Suprasetter A 52

Including equipment

Suprasetter PCI Interface card

Prinect CtP User Interface SW Debris removal unit (DRU)

Including expansion equipment Integrated punch HD 425 Auto Top Loader (ATL)

Stacker PST 26-65 serial number 2113261363 Automatic stacker

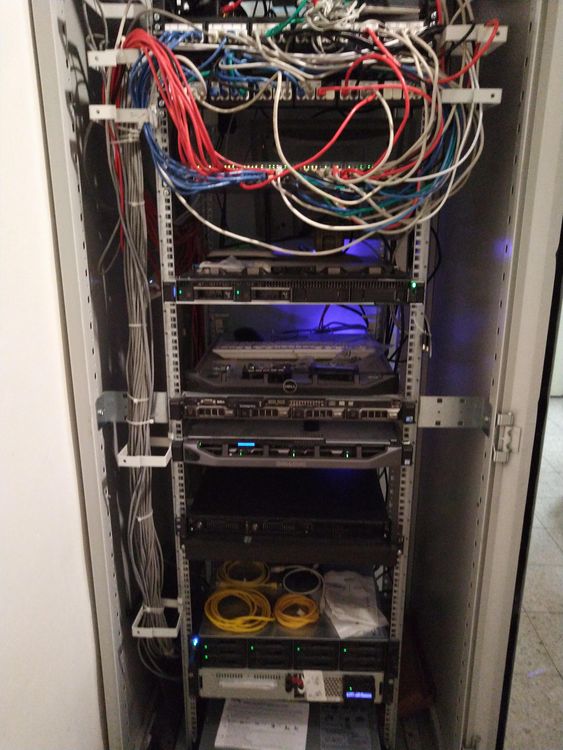

Prinect Workflow

HW DELL RIP PowerEdge R410

RIP SW Prinect MetaDimension 52 Prep v. 7.5

RIP SW Prinect MetaDimension Hybrid Screening IOP-REC RIP SW Prinect MetaDimension lnRIP Trapping 52 SW Prinect MetaShooter 52 v. 4.5

Impositioning and sheet assembly SW Prinect Signastation 4.5 52 HW DELL Prinect SignaStation

Including 2x 20” LCD monitor HW DELL MetaDimension RIP Sewer

Including 1x 19” LCD monitor

HW DELL MetaShooter workstation Including 1x 19” LCD monitor

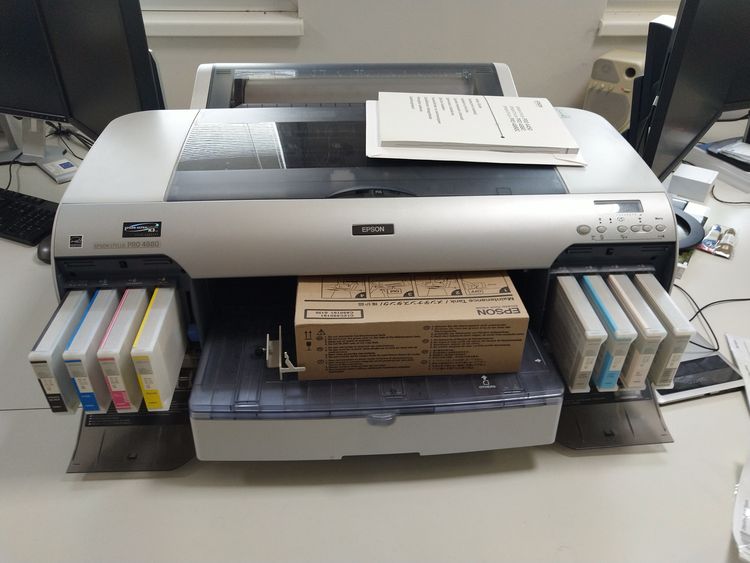

Proofing solution

RIP SW Prinect MetaDimension 7.5 proof 52 HW Epson stylus Pro 4880 serial number PF11025193 SW Prinect Quality monitor

HW X-Rite Eye One serial number 343327

SW for colour editing SW Prinect Profile Tool SW Prinect Color Editor

Technical specification for Suprasetter A52 Generation III platesetter

Design:

Plate handling

Feeder magazine capacity Plate type

Min. plate template Max. plate template

Max. exposure format Plate thickness Exposure resolution

Platesetter dimensions Weight

Accuracy

Repeatability Productivity Position for punches

Exposure data input

Working environment temperature range Working environment humidity range Power supply

Max.Current at 200 V Max. Consumption

Average consumption during exposure Average operational consumption Consumption at rest

Consumption in standby mode Thermal radiation

Noise level of equipment

Safety certificates

Thermal CtP platesetter with external drum Automatic, the operator puts the cassette containing the plates in the automatic feeder, the set-off paper is separated, the plate is separated from the stack by suction cups and put on the feedboard, then fixed by front rail, sliding back gripper and vacuum on the rotating exposure roller. The plate is exposed perforated and returned to the feedboard.

From here it is transported to the delivery feed bridge and via this bridge to the developer. 50/100 plates 0.3/0.15mm thick

Aluminium plates with layer sensitivity 830 nm 240x240 mm 670x530 mm

650x530 mm 0.15-0.30mm

2540 dpi

1.550 x 2.371 X 1.350

860 kg

± 25 pm for set of 4 following plates in view of perforation position

± 5 um for two consecutive exposures on the same plate up to 20 plates/hour depending on sensitivity of plate spacing 220/425/550 mm

Prinect MetaDimension, Prinect MetaShooter 170 to 30 oc

30 % to 70 %

200-240 Volts 50/60 Hz

6.0 A 1200 w 700 w 550 w 270 w

Max. 4300 kJ/h, average at exposure 2500 kJ/h (2389 BTU) less than 64 dB

GS, c ETL us, GOST / CE, FCC, CDRH, CAN

The automatic plate feeder requires an external compressed air source to work Compressed air requirements: Dry, oil-free, min. pressure 6 bar, max. pressure 8 bar with dynamic consumption. Permanent air volume available min. 150 l/min, dust particles max. 5 um

Expandability:

Increase in exposure speed up to 27 plates/hour Upgrade to B2 format

Expansion for exposure of plates for printing lenticular films

Expansion for security-paper applications — option 5080 dpi Operational area of platesetter 2.67 m2

Prepress Manager

Prinect Prepress Manager is automated prepress workflow. Based on the international standards PDF and JDF, it automates and integrates all the tasks and activities in the prepress process from the generation of PDF pages to output of proofs and plates. In view of its modular architecture allowing the addition of further expansions and modules, each Prepress Manager can be configured for specific user needs and also adopted in relation to the ongoing change of these needs, whereby the security of this investment is ensured.

Prepress Manager includes the following functions:

Centralised management and monitoring of jobs using the application Prinect Production Cockpit, which offers the following functions:

System administration

- Central administration of system and its parts Template Editor

- interactive generation of process plans - template sequences of automated data processing operations

Manual page handling

- allows editing of individual pages in system, the pages are displayed as proofs or a list with indication of editing state

Imposition — Base

- interactive selection of imposition layout and automatic imposition of pages in layout

Interactive imposition — interactive shaping/adjustment of imposition scheme via Prinect Signastation with Prinect Cockpit environment.

Imposition — Automatic scheme Extension

- In connection with Prinect Signastation it generates the corresponding number of signatures based on the number of pages of the job Imposition — Readers Spread

- In cooperation with Prinect signastation the imposition layout of a job for checking the order of a publication’s individual pages is generated.

Manual JDF Gate

- It generates a new job in the Prepress manager, it takes the name and number of the job from the information system Contone Soft Proof -

Halftone soft Proof on bitmap proof image

- Bitmap proof on screen Pantone Library

- use of Pantone libraries

Automatic processing of jobs in Prinect Prepress Manager, which includes the following functions: Hotfolder

- automatic generation of hotfolders serving for insertion of data files for the given jobs without use of Prinect Cockpit

LoadBalancing

- optimises load balancing during multiple use of several modules (normaliser...) Normalizer

- automatic conversion of PostScript and EPS files to PDF according to individually set conversion rules

CEPS converter

- conversion of dt TIFF-IT/PI to PDF Splitter

- splits multipage PDF document into separate paged PDF files in order to speed up the access to the individual pages in the case of their editing

PDF Merger

- merges individual paged PDF files into a single file in order to speed up the processing by the PDF Optimizer

- Optimisation of PDF documents (reduction in size of files conversion of text to curves etc.) Preflighter Advanced

- checking and corrections in PDF documents (fonts, fine rules, pictures etc.) Color Carver - fully automatic colour conversion for use of Heidelberg CMM for conversions of data between Color Carver

Color Carver Plus (for Hexachrome)

- conversions for multicolour colour spaces (hexachrome) Automatic object Trapping (PDF Trapper)

- Module performing automatic native trapping in PDF data based on rules configured in relevant process plan. Uses patent technology of the firm Heidelberg

Mark Imposer

- Generation of JDF commands for MedaDimension for creation of imposed print sheet with corresponding printing marks (replacement of dynamic marks for their concrete form)

Auto assigner

- Automatic assignment of individual pages to the relevant positions in the imposition layout on the basis of data file name convention

Auto page

- checking completeness of given file of pages and their sending for further configured processing operation Autosheet

- checking completeness of press sheet and its sending for further configured processing operation PDF Approval Mail

- correction and approval cycle between system and customer on the basis of sending of checked/corrected pages/press sheets

Job exchange

- support for import and export of all order JDF order data, including job content from/to Prepress manager in format ZIP archive Signa Server

- Automatic generation of imposition layouts based on definition of job in information system Prinect Prinance Auto assigner

Backup

- automatic backup of system production data for eventuality of crash (uses system resources of Windows Server operating system)

PDF Imposer

- imposition of press sheet to full PDF in high definition

Interactive optimisation of PDF document in environment Prinect Cockpit using set Prinect PDF Assistant 4.0 plug in modules for Adobe Acrobat. Includes the modules:

Accelerated View Geometry Control Separation Control Status Control PDF Report

Page Construction

Interactive checking of trapping in PDF documents in the environment Prinect Cockpit using Prinect Trap Editor - plugin module for Adobe Acrobat. Contains the function: Prinect Trap Editor — Trap Viewer, Trap Changer

Interactive checking of object’s number of inks in PDF documents in environment Prinect Cockpit using Prinect Color Editor - plugin module for Adobe Acrobat. Contains the function: Prinect Color Editor — Color Viewer

Input formats:

PDF v. 1.2-1.7 PDF/X-1a:2003 PDF/X-3:2003

Postscript Leve12 and PostScript3

TIFF/IT-PI

ZIP for import of jobs from Prinergy 2.1, Printready 2.x, Printready 3.x and Prepress Manager 4.x JDF 1.3 for import of MIS jobs

(only with module Auto JDF Gate Prinance or MIS Connector module) JDF 1.3 for import of imposition schemes from Prinect Signa Station

Output formats:

PDF documents in format PDF 1.3 or PDF/X

ZIP for export of Prepress Manager P 4.x jobs JDF 1.3 merging into MIS systems using JMF with Prinect MetaDimension: output formats supported by Prinect MetaDimension

Delivered items

Licence key for: 1x Prinect PDF Assistant

Licence key for: 1x Prinect Prepress Manager Engine Trap Viewer, Trap Changer function in Prinect Trap Editor Color Viewer function in Prinect Color Editor

Requirements/Limitations

Use of operating system Windows via service Bootcamp on Apple HW can cause problems with network services

The function Contone Soft Proof requires linkage with Prinect Metadimension 2011 The function Halftone soft Proof requires linkage with Prinect Metadimension Prep

2011 or with Prinect Metadimension 2011 with released module TIFF-B Export Prepress manager 2011 supports linkage with Prinect MetaDimension version 2011 Prepress Manager 2011 supports linkage with Prinect Signastation version 2011 Prepress Manager 2011 supports linkage with Presroom Manager version 2011

Prepress Manager 2011 supports linkage with Integration Manager version 2011

The function Imposition — Automatic scheme Extension requires that SW Prinect SignaStation is running on the same computer as SW Prinect Production Cockpit.

The function PDF Approval Mail requires Adobe Acrobat Professional version 8 or later