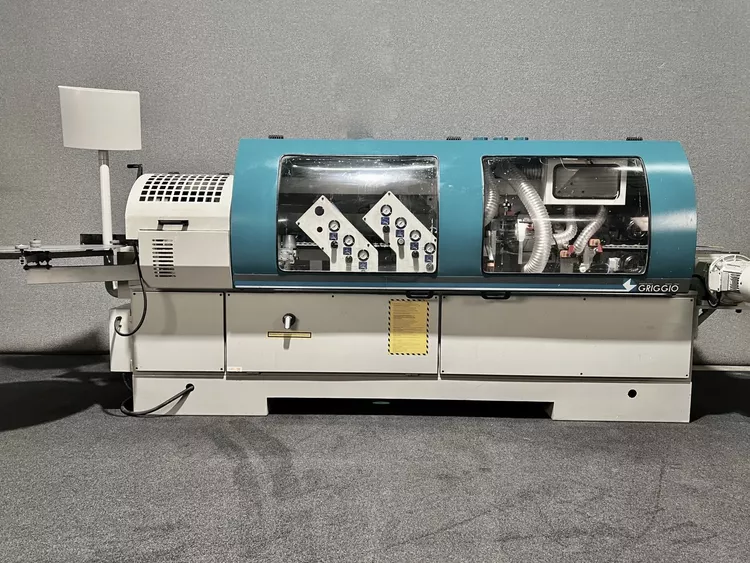

Griggio GB4-8

EUROPE (Western and Northern)

Automatic single-sided edge banding machine for processing edges

in rolls or strips in PVC, ABS, melamine, veneer and solid wood.

The machines are complete with:

• Roll support plate diameter 800 mm;

• Automatic strip edge feeder

• Hot melt glue tank with rapid heating system, capacity 4 lt.;

Glue tank with electronic temperature control up to 200°-130°.

During the time when the machine is not working, the temperature automatically drops from 200° to 130°.

2 trimming units;

* 1. Trimming unit with pneumatic system for trimming edges from 0.4 to 1 mm. with automatic edge return;

* 2. Trimming unit with pneumatic system for trimming edges in PVC and ABS thickness max. 3 mm.

• Cutter radius 2 mm for processing edges and solid wood up to 8 mm.;

• Separate ABS container for the chips;

Buffing wheels diameter 150 mm.

Feed speeds 12-16 m/1’

(No. 1 speed 12 m/1’ – 39Ft/1’ Volt. 230/60 Hz);

• Adjustable control panel at eye level

• Adjustable edge pressure unit complete with 3 rollers with digital display:

1 motorized roller with pneumatic independent and adjustable pressure system

2nd and 3rd loose roller with pneumatic independent and adjustable pressure system.

Support rail with rollers for wide panels;

Automatic adjustment of the height of the units with digital displays;

Central suction;

Top pressure, with double row rubber rollers with digital display of the top pressure

Machine equipped with:

Gluing

Capping

Milling

Drawing blade

Buffing unit

Objective defects: Paint dirty, partially chipped, hood glass cracked (replacement not a problem as it can be replaced easily and inexpensively)