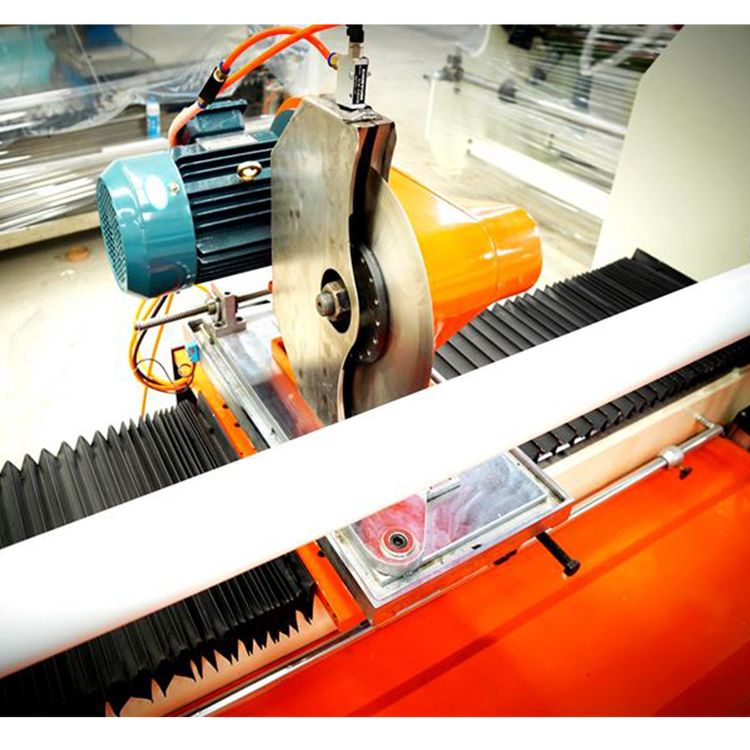

GL-701 Clear Packing Sticker BOPP Adhesive Tape Cutting Machine

China

GL-701 Clear Packing Sticker BOPP Adhesive Tape Cutting Machine

For cutting BOPP / PVC / PE /PET/ EVA / 3M/Mylar / masking /foam / cloth /double sticky /Kraft / aluminum duct tape etc.

Get production video link as below:

https://www.youtube.com/watch?v=ueUk-vyfJS8&index=9&list=PLpA-R5J_9zjjU7APfoP7dAaR5Hlhypees

GL-701 Clear Packing Sticker BOPP Adhesive Tape Cutting Machine

Max. working width(mm)

1300

Cutting width(mm)

1--1300

Cutting accuracy(mm)

±0.05

Paper tube inner diameter(mm)

25.4---76.2

Max.cutting diameter(mm)

400

Max. cutting speed (cuts./min)

35

Weight

2500kg

GL-701 Clear Packing Sticker BOPP Adhesive Tape Cutting Machine features:

1. Automatic control of PLC system with LCD touch screen control panel , 20 modes for size setting each time & auto changing when cutting. Easy function setting, user-friendly interface.

2. Auto liquid silicon water spray cooling system: to avoid the adhesive sticking on the blade and ensure the smooth cutting.

3. AC motors for cutting blade and cutting shaft with inverters speed changing .

4.Positioning system for cutting: servo motor to control more accurate position.

5.Sliding system,high precision liner sliding track and ball screw.

6. Auto cutting angel adjustment ±8° can well protect the cutting blade as well as guarantee the cutting edge flatness.

7.Single shaft, single blade.

We are in ZHENGZHOU city, HENAN province, in north China.

Two hours from Guangzhou to our factory by air.

90mins by air from shanghai .

We directly pick you up at our Xinzheng International Airport.

Our factory address:

Xueyuan Road NO.168 ,Mazhai Industrial Park,Erqi District, Zhengzhou City ,Henan Province,China.

FAQ

1.What are the raw materials?

And how to get to know the machine production?

Bopp film & adhesive glue & paper tube.

Machine production/hour == 1hour square meter the machine runs ( speed* 60min* coating width)

1 roll tape square meter ( width *length)

2.How many machines required to process gum tape / adhesive tape?

What optional machines needed for this line?

Two machines----- one our tape coating machine & one tube cutting machine.

Optional machine--- air compressor etc.

3.Can your machine make different size tapes?

Different width tapes---- using different size mould.

For ex. u want to make 4cm width tape, u will need 4cm width mould.

u want to make 4.5cm width tape, u will need 4.5cm width mould etc.

4.Manufacture tape with and Without PRINT on the same machine as required by our client?

Yes, printed tapes & color tapes & clear tapes are make on the same machine.

One or two color online printing on our machine.

5.When we need Finish Product without any print, can we skip the print part during production?what is your printing method?

YES. If no need printing, then skip it and directly coating glue.

We use engraving printing roller for printing.

6.If we change the type/color of BOPP roll, can we make different type of tape?

Color tapes --- need add different color paste in glue for different color tapes.

This line is designed specially for making BOPP tapes .

7.What is the expected life of Motor and other parts?

The host equipments are entitled to one year warranty & free replacement & life time technical support service.

8.For the Raw material - BOPP Film - Do we need tape rewinding machine to make small roll from jumbo roll?

No. There is professional BOPP jumbo roll tape slitting & rewinding machine, which can finish slitting & rewinding same time.

9.The voltage in our country is different from yours,does the machine can be changed?

Yes.

10.Are your engineers available to oversea service ?

Yes. Our oversea service centers are updating and more complete.

Our Service

We are established in 1990, specializing in manufacturing large, medium and small sizes of adhesive tape making machinery including coating, slitting , rewinding , cutting ,printing ,lamination ,packaging machines , paper core making machine etc.

Sales all over the world!!!

Why Choose us?

1. Product quality: Quality tesing records in manufacturing & expriments.

2. Price guarantee: Fine & brand quality materials,parts on machine.

3. Delivery guarantee: Related brochures along with delivery:

operation&maintenance;

installation drawing;

operation books for relater parts of outer supply;

spare parts list and stand accessories.

4. After sales guarantee: The seller is responsible for changing the parts which have the quality problem of the machines in one year,but except from the wearing parts and the quality problem were leaded by wrong operation and other man-made factors,and the quality problem should be confirmed by two sides.