Ghioldi s.55-75-55, d.300, w.1600 mm. 300 kgh

EUROPE (Western and Northern)

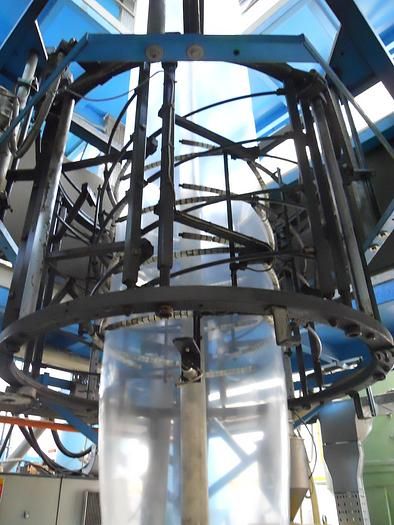

This 3-layer blown film line has been constructed according to the high Italian quality standards.

The line is constructed in sturdy carbon steel on a 3 level bolted structure complete with stairs and platoforms, compliant with CE safety regulations.

It makes perfectly aligned, automatically discharged reels and you can obtain multiple rolls on rewinder.

Originally purchased for 6-pack bottles shrink film, its versatility allows different uses for industrial and commecìrcial purposes.

The line handles LDPE LLDPE HDPE Metallolcene BLENDS,prime,repro and more. You can make your own blends to meet a wide range of requirements.

Plastic films are required now to have a lower impact on the environment. With this line, film can be as thin as 25 µ.

Gravimetrical dosing units allow you to add masterbatches and different additives.

The Corona treatment will prepare material for further printing, while the gusseting units will allow you to collect a wider width on the 1,680 mm.

The line can be seen in production on appointment to check how good its conditions are. Mounted in Jan.2014, after a total reconiìditioning, it has been scarcely used ever since, simply because the market demand of the product it was bought for dropped soon after and the Owner had other businesses to attend to.

Our present offer includes disconnection (duly marking the matching wires) complete dismantling, loading on the 4 OT 40'fcl, Customs duties in export and shipment CIF ITALIAN PORT from where the Buyer can pick up to the final destination.

The Buyer is invited to send his own technicians to record, watch and give a hand during disconnection and dismantling, so that it will be easier for them to remount at destination.

Including:

N. 2 extruders diam. mm.55, 78 kW 30 L/D

N. 1 extruder diam.75 mm. 142 kW, 30 L/D

n. 3 lever type screen changers

Melt control system

3-layers still die mm.300 gap. mm.1,4

IBC cooling system

AM500/2 dual flow cooling ring

2 temperature exchange batteries

electrical cabinets with Mitzubishi inverters

Oscillating pull-off system

FIFE web guider

Bubble driver with vertical adjustment and sensor for automatic bubble inflating (maximum diameter 1175 mm.) for 3.386 mm.web circumference)

Back to back winding station 1680 with 4 expandible mandrels

Automatic film cutting

Automatic reel unloading system

Bolted 12 m.tall tower with 3 storey, ladders (10 m. at 3rd floor + 2 m. pull off)

Cason corona treatment

DOTECO gravimetrical units (1 for each extruder)

Some spare parts included

manuals, drawings, English program for PLC.

N.4X40′ OT fcl

output : 300 kg/h depending on materials

In our video you can see the line running with EXXONMOBIL virgin material :100% ENABLE

If you have time, find a comfortable seat, get a drink and watch our detailed 25'video