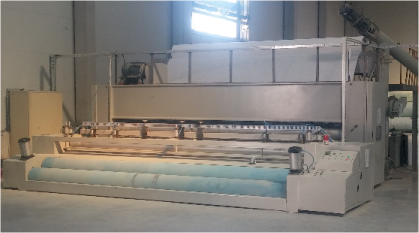

Geosynthetic clay liners and concrete carpet production line

EUROPE (Central and Eastern)

Main technical parameters:

Maximum width of finished products: 5300mm

Weight of products: 3000~6000g/m2

Line speed: 1.5m~3m per minute (it depends on the weight and thickness of product)

Raw materials:

(1) Nonwoven geotextile (width≥5000mm.)

(2) PP woven geotextile (width≥5000mm.)

(3) Bentonite powder granulation (60~220 microns), or bentonite granules from 0.5 to 3 mm

The line can produce concrete carpet with a thickness from 7 mm to 13 mm

Name of equipment and main technical parameters:

(1) Unwinding device of woven geotextile

Working width: 5300 mm

Diameter of Roller: 299 mm

Line of Speed: 1–3 m/min

(2) Tension Bracket

Working width: 5300 mm

Diameter of Roller: 219 mm

(3) Bentonite silos

Big Bags with bentonite powder or bentonite granules are lifted with the crane to the silos, then big bags are opened, and bentonite is poured into the silos.

(4) Dosing unit

From the silos bentonite is going through the dosing unite to the vibrating screen.

(5) Vibrating screen

Bentonite powder goes through vibrating screen so that the bigger particles would be removed.

(6) Elevator (screw conveyor)

Bentonite powder is feed to the Screw conveyer.

(7) Bentonite dosing machine

This machine is distribute bentonite powder on the woven geotextile.

Then it is flaten by scraper.

Working width: 5300 mm

(8) Unwinding machine of nonwoven geotextile

Working width: 5300 mm

Diameter of Roller: 299 mm

Line of Speed: 1 – 3 m/min

(9) Needle-punching Machine

Working width: 5300 mm

Needle frequency: 450 n/min

Needle stroke: 60 mm

Needle density: 3500 n/m max.

Line speed: 1 --- 6m./min.

The needle plate is made by Magnesium alloy with hole φ1.83mm, which are distributed random by computerized design.

The part the “eccentric” of Needle- punching Machine is with SKF bearings.

(10) Winding and slitting machine

Working width: 5300 mm

It is suitable for winding, edge-cutting and measurement of finished product.

It can cut the product into the required width and length for packing.

It has photoelectric counter, 4 pneumatic cutting knives in longitudinal direction and 1 flying

knife in transverse direction.

(11) Electric Control System

“Siemens” PLC control system with touch sreen (pannel)

All speed regulate are controlled by frequency conversion

Three-phase pressure: 400V (or according to customer’s request)

Frequence: 50Hz (or according to customer’s request)