Fully equipped 3050x2050mm CNC Control

EUROPE (Western and Northern)

CNC cutting table: milling / cutter / registration / creasing

Fully equipped 3050x2050mm

As part of a renewal (and a lack of space),

I am separating from my Signmate 1000

3x2m cutting table. The removal must take

place during the week of 8/11. Until then, it

can be seen in production.

I bought this CNC in 2017 and gave it a little

makeover. It allowed me to start and grow

the cutting activity within the company in

such a way that I now have to replace it with

a faster milling machine. Ideally, I would

have liked to keep it as a second machine

because it works perfectly, but our

workshop area just does not allow it.

This is a cutting table supporting

3050x2050mm plates, like other CNC flatbed

from Zund, Aristo or Esko.

It is equipped with a 1.1kW Precise SC-P60

liquid-cooled spindle (up to 60,000 rpm), an

EcoCam TCM-4 cutting cutter, an EcoCam

TCT-2 creasing module, a camera optical

registration (to wedge the cut after printing),

a turbine for the suction of the plate, and a

chip vacuum cleaner.

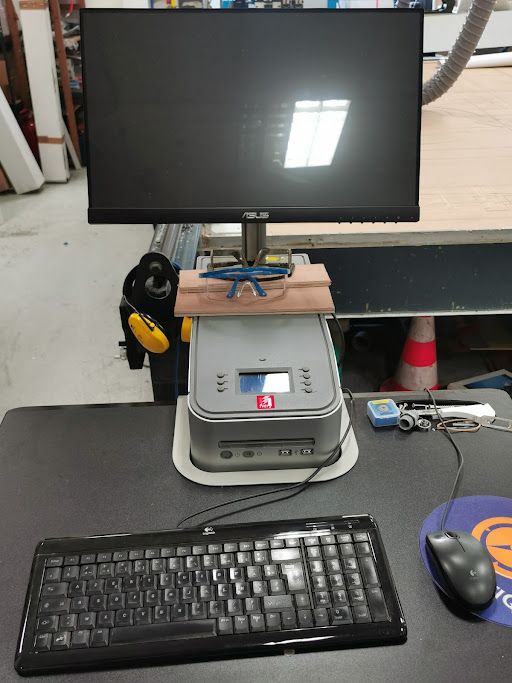

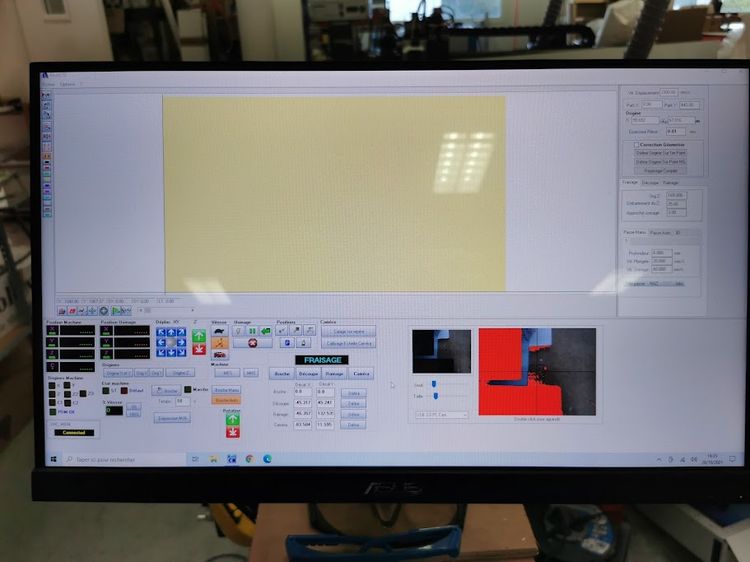

The standing position control station with

touch screen and the Multi-CN piloting

software under Windows 10 are included.

It is the ideal machine to start in signage:

versatile, it easily cuts aluminum composite

sheets (Dibond, Dilite, Alupanel, etc.) or raw

aluminum, expanded PVC (Forex, Foamlite,

etc. ) or rigid, PMMA (Plexiglas, Altuglas,

etc.), solid or cellular polypropylene (Akylux,

Biplex, Akyplak, etc.), MDF, and magnetic

sheets, PVC tarpaulin, paper, etc. on

thicknesses ranging from a few tens of

microns to 30mm and more (we did not

need to go beyond) depending on the

materials.

Its 3 tools allow you to drill, mill, engrave,

crease and cut with confidence most of the

materials available on the market. There was

even a lubrication system for milling and

engraving hard materials (stainless steel or

other) but it was not useful to put it aside.

Floor area excluding control post:

4.95x3.05m

Maximum useful surface of the plate

(variable according to the tool used):

3.2x2.1m

Passage under head: 55mm

Speed: 100mm / sec

Power supply: 380V

Compressed air pressure: 10 bar (only

necessary for tool change)

Parts included: 1 camera, 2 wrenches, 2 nuts,

4 pliers (3 + 4 + 6 + 8 mm), 1 used Precise SC-P60 pin in

perfect condition (I am a very far-sighted person ;-))

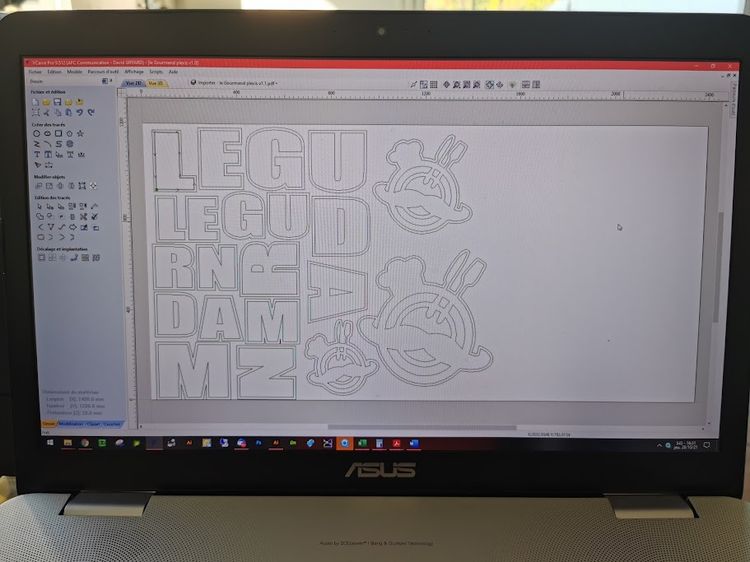

Control: 3Ghz head-up station with 21-inch Windows 10

touch screen, Multi-CN control software supplied. For the

generation of the files we use VCarve Pro (not included

with the machine).

Other items included: chip vacuum cleaner, vacuum

turbine

Requires an air compressor, not supplied.