Flexowash Anilox Sleeve Cleaner 992XL Solvent Distillation And Cleaning Line

United Kingdom

FLEXO WASH ANILOX SLEEVE CLEANER 992XL SOLVENT DISTILLATION AND CLEANING LINE

Capacity: 2 sleeves each washing cycle

Fully automatic and extremely gentle cleaning process for all types of ink

Time saving and user friendly plugin play technology

Minimal maintenance

Long unit life time

Low operation costs

Environmentally friendly cleaning

In all the units from Flexo Wash the cleaning process is 100% automatic,

so the operator is capable to prepare another print job, while the cleaning equipment is cleaning the items

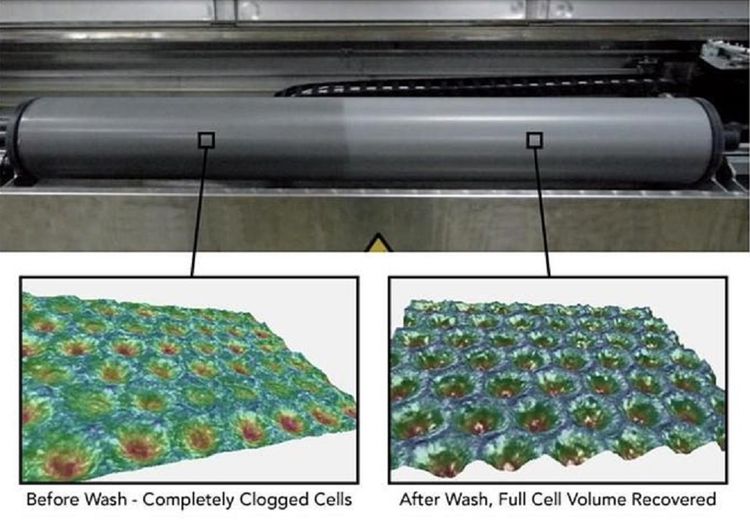

Washing: sleeves rotate while heated liquid is sprayed onto the sleeves for about 5-15min

Liquid makes the ink in the cells crack and loosen from the cell walls

Draining: when the washing cycle ends the sleeves continue to rotate

while the cleaning liquid is drained off and runs back through a filter into the tank for reuse, duration is 2-3minutes

Rinsing: to remove the cracked ink particles the sleeves are rinsed by means of high pressure water

High pressure nozzle is mounted on a slide, which is moving along the sleeves, duration is 1-2minutes

Drying: sleeves rotate while an air stream blows off water

Drying nozzle is also mounted on a slide that is moving along the sleeves,

duration approximately 1-2minutes depending on sleeve length

Microprocessor control: unit is controlled by a microprocessor and the operator

can easily change the various settings as e.g. washing time, rotation speed and temperature

Washing programs have been pre programmed according to the following:

Program 1: washing time 5 minutes

Program 2: washing time 10 minutes

Program 3: washing time 20 minutes

These settings are password protected but can be changed

Pumps: unit has one diaphragm pump for spraying of cleaning liquid

and it has one high pressure pump for high pressure rinse water

Filter: unit has one filter, 50 micron, which will collect the ink particles

This gives a longer lifetime of the cleaning liquid

Filter is placed under the washing chamber and can easily be changed or cleaned,

it is recommended to change the filter once a month or after approximately 100 wash cycles

Nozzles: unit two types of nozzles are present, air nozzles and high pressure nozzles

Air nozzles are made of PWDF and the high pressure nozzles are made of stainless steel

Tank of stainless steel: unit has one tank for cleaning liquid, optional two tanks

Tank is placed underneath the washing chamber and it has a built in heating element

Cleaning liquid can easily be filled into the tank through the filling funnel