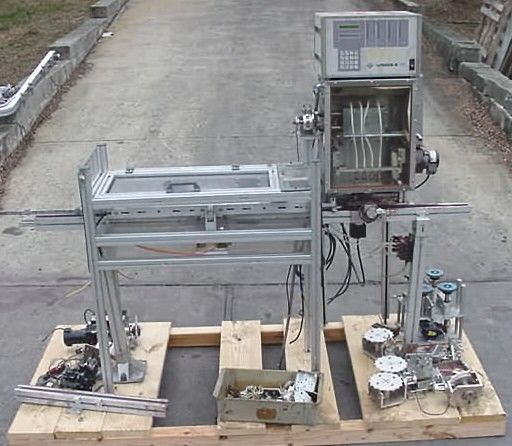

Custom built Hot Pour Filler

AMERICA North (USA-Canada-Mexico)

4 piston, electrically heated,

designed by JG Machine Works & used for hot pour cosmetic filling,

2″ x 7′ long extruded aluminum conveyor body

with pneumatically operated 4 container indexing station at filler,

1/2″ diameter pistons operated via motor driven

Acme screw with threaded micro adjustment at each piston,

3/16″ diving fill nozzles mechanically driven

& set at 1.5″ centers, pistons, valve block,

fill nozzles & product feed line housed in stainless steel

heated box with hinged see thru front cover,

electric heater & circulating blower,

product feed line has inlet & outlet for continuous

sources of material from heated process,

42 long discharge tunnel equipped with ceramic heaters

& circulating fans to smooth filling imperfections

following filling, a variety of indexing wheels

& miscellaneous parts & system components