Coated Diamonds/CBN

ASIA (China - Taiwan - HKG)

With more than 30 years experience, E-Grind provides various types of coating onto diamond and CBN mesh and micron powder. As per the bond system, E-Grind supplies customers with the most suitable coating onto the superabrasives grits. The coating enhances the retention ability between diamond/CBN and the bond, improves the heat resistance performance, electric conductivity characteristics.

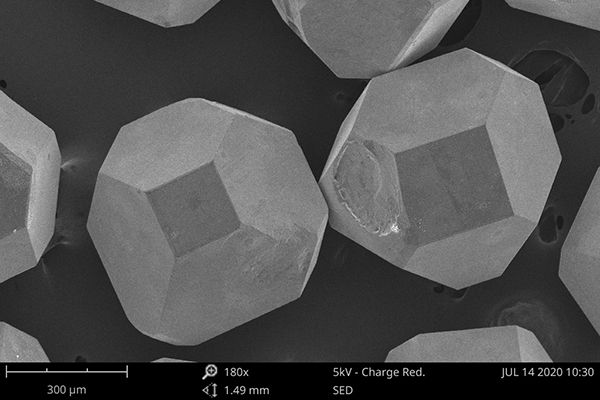

Electroless Ni Coat

Provide premium mechanical retention to diamond or CBN, with better heat dissipation, higher durability and smooth surface finish.

Application: Resin bond system

30%, 56%, 60% coated (by weight) is available upon request.

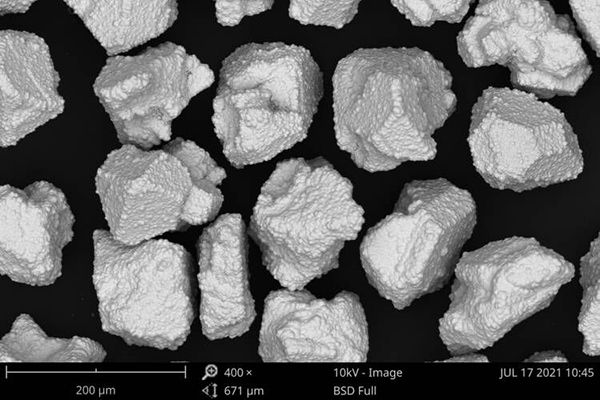

Electrolytic Ni coat

Provide the mechanical retention to diamond or CBN, with better heat dissipation, higher working efficiency and improved durability.

Application: Resin bond system

30%, 56%, 60% coated (by weight) is available upon request.

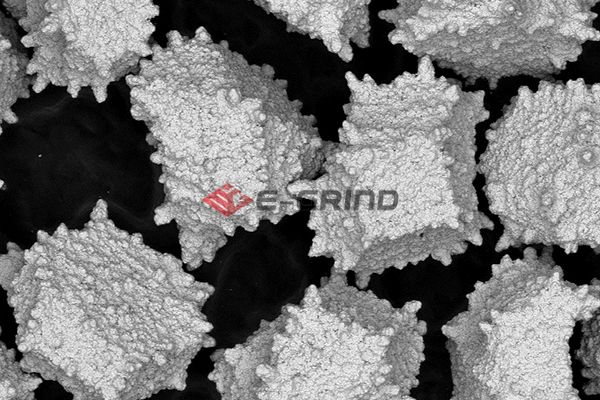

Titanium coat

Keep diamond or CBN grits away from oxidation and graphitization at high temperature; provide better retention ability to diamond or CBN with longer using life.

Application: Resin Bond and Metal Bond system

2% coated (by weight) is available upon request.

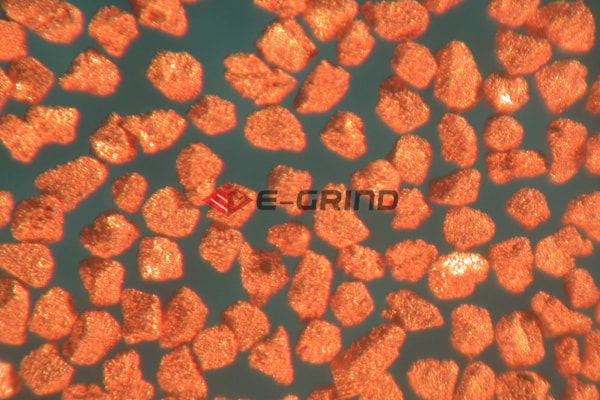

Copper Coat

Have superior ability in dry grinding applications. Provide better retention of diamond or CBN with excellent heat dissipation.

Application: Resin bond system

50% coated (by weight) is available upon request.