Befama, Temafa, Hergeth Complete nonwoven line

EUROPE (Western and Northern)

Complete used nonwoven T shape production line.

Capacity 200kg/h

This special line can produce a variety of nonwoven fabrics, such as for mattress, insulation, furniture, auto, garment, separating layer in multi composite systems and others. The weight per unit area that can be produced ranges from 200.......2500 g/m² depending on the raw material input. Raw material input: natural and man-made fibers PES 11.6 - 3.3 dtex, VIS 1.7 dtex, PP fibers 11 to 17 dtex, glass fibers 12 to 24 µm and recycled fibers. Processable fiber lengths: up to 80 mm. The capacity of the line is max. 400 Kg/h, depending on raw material input and basis weight. Width of the finished product 3000 mm. Feeding of various cover webs is possible.

Year of the line: 1986/1990, constantly modernized and overhauled. Electric and control system up to date, EL: 380 V / 3 Ph / 50 Hz, power of the line: 120 kW. Space requirement: L 30 m x W 20 m H 4 m

Consisting of:

01 x Temafa bale opener

N1 Befama- carding machine (left)

01 x Feeder

01 x Befama - carding machine, working width 1800 mm, type :previous generation of CU 641, consisting of: Ripper, breast roller D= 900 mm with 1 worker/turner, transfer roller, main cylinder 1500 mm with 4 workers/turner, doffer 800 mm, chopper. Capacity: 200 Kg/h

N2 Befama carding machine (right) - Analog N1 Befama carding machine (left)

All rollers are equipped with Graf clothing.

The fineness of the Graf clothings on the two carding machines:

Reel: VE 5015 -12

Transfer roller: VG 5030 -10

doffer: VF 5040 -16

turner: VE 5015 -10

Worker VE 5015 – 8

01 x Hergeth- cross lapper, input: 3000 mm, output: 4000 mm

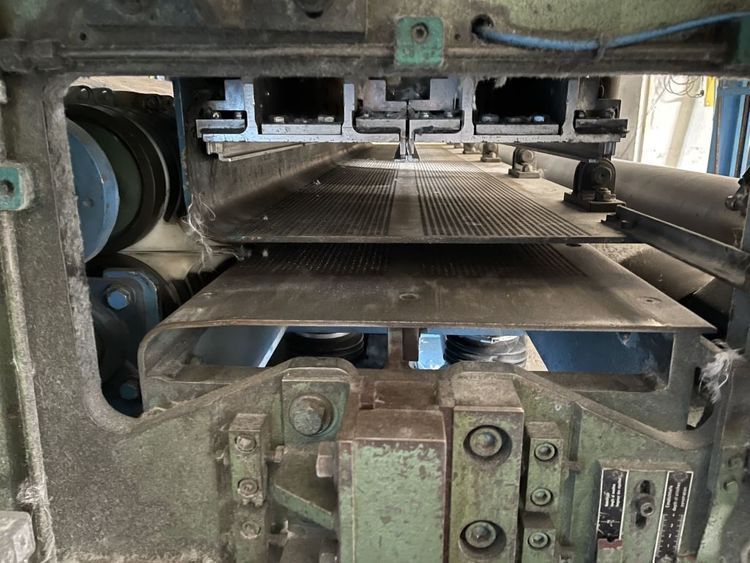

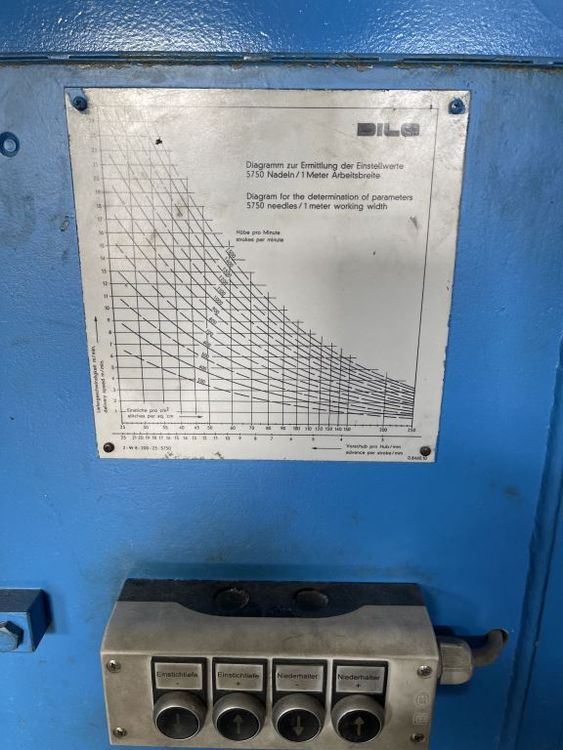

01 x Dilo needling machine, type Di-Loom OD-ll/30, with CBF 25, working width 3000 mm, stroke: 60 mm, 12.000 needles ( 2 x 6.000 needles), 1100 strokes/min.

01 x winder with 4 high-speed knives and cross cutter with high-speed knife, roll diameter 1500 mm

01 x Autefa- edge trim ripper AB 800 mm, aluminum boards with slanting foundation. The edge trim preparation is done online, the fibers are directly fed back to the carding machine.

Additionally many spare parts, fans, new Graf clothings