Barmag POY MICROFILAMENT EXTRUSION SPINNING LINE

EUROPE (Western and Northern)

Barmag extrusion spinning line

With 12 positions

72 spinning ends

For PET POY

Microfilament yarn

Installed in 1998/99, started up in 2000

Only used 3-4 years, thereafter maintained and kept mothballed

In good condition

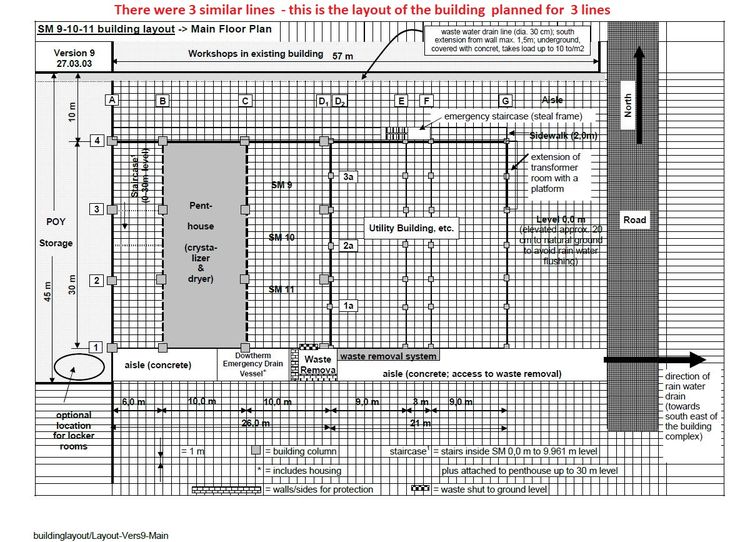

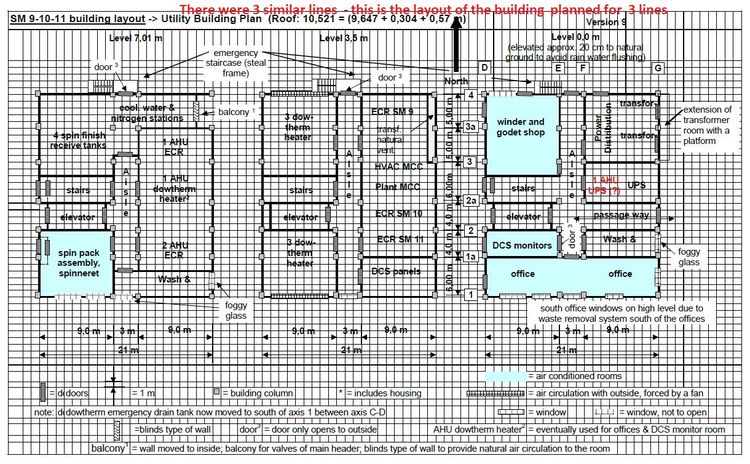

the pure space of the is about 10m x 10m x 10,9m height

Layout in the photo is for 3 lines.

Consisting of:

1 extruder barmag 12 e 8

Spin beam including spin packs & spin pumps 3,5 cc/u

Spinnerettes 100mm dia, bottom loaded, designed for high counts micro & supermicro

Polymer manifold extruder to spin beam

Dowtherm manifold for spinbeam and polymer manifold

Quench system including finish system, spinfinish jets by kyocera

With conventional quenching cabinets + evosepeed& radial type

Take up units, including:

Take up sections / platforms / ladders

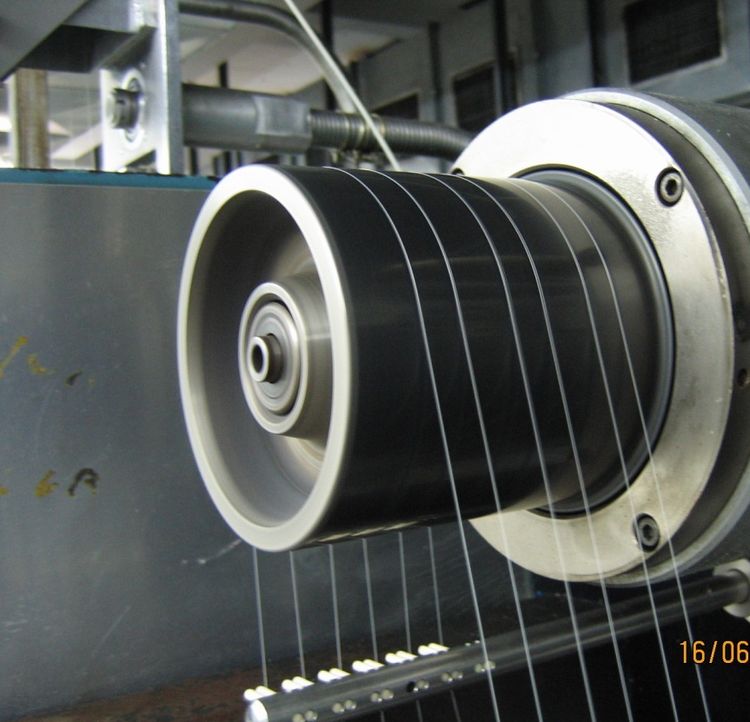

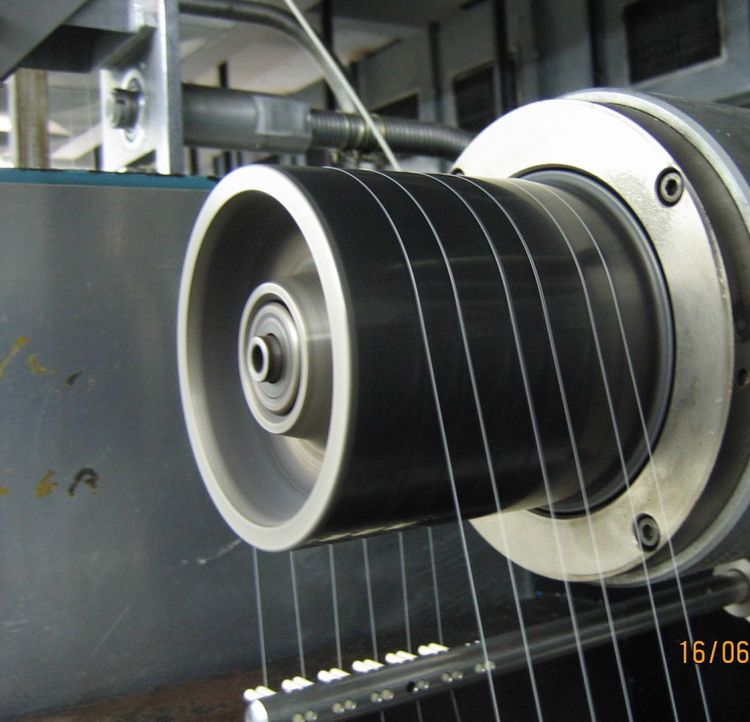

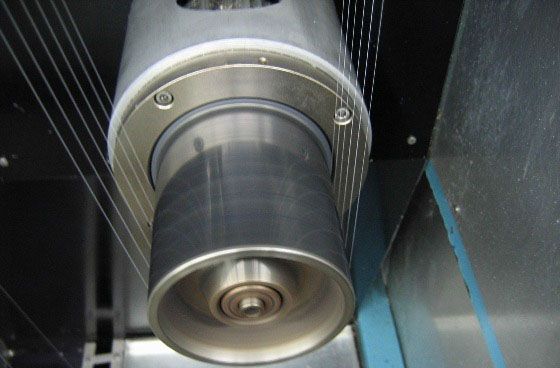

Cold godets, one pair per position

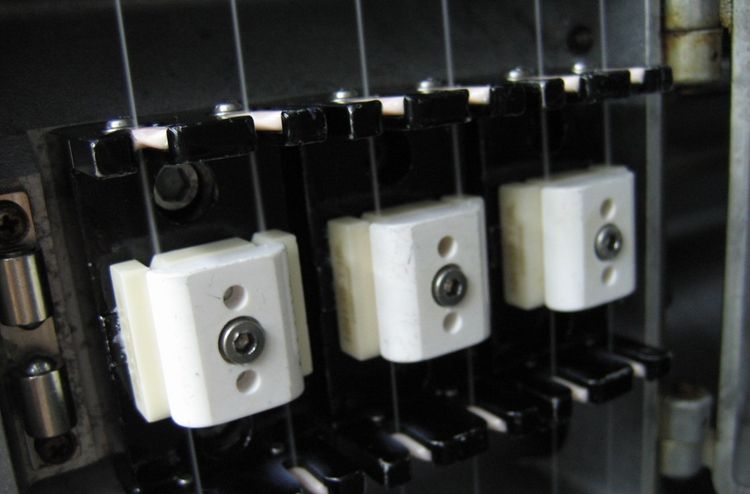

Interlace system with heberline intermingling jets

Yarn suction system

12 winders, barmag cw6-1200/6 6 ends per chuck

+one spare winder

Electrical control system, comprising of :

•electrical control panels for extrusion & spinning

•electrical control panels for take up & winding

•electrical control panels for dowtherm heating

•dowtherm system, comprising of:

•dowtherm heaters for manifold and spinbeam

Chip drying & conditioning system, comprising of:

Fluid bed drier

Inlet hopper

Head hopper

Air heater column

Pre crystalizer duct

Column bottom (dryer)

Vibro feeder & control panel

Miscellaneous :

Spin pack preheating oven

With available spare parts

Technological information:

Yarn range from 100 up 300 den (final) / 34 –144 filaments

Extruder throughput from 195 kg/h up to 523 kg/h

Total 72 threadlines

Mechanical speed from 2500 up to 6000 m/min

Bobbin size 440mm, max weight 20 kg, tube id 110mm

All major parts such as extruder, spinbeam, spinpumps, spinpacks, godets,

Radial quenching, take-up frame, winders are made by barmag (manufactured in germany)

Capacity of 1stchoice poy yarn is approx. 2800 mt/ year

Approx. Capacity as example :

100 den -> 2750 t/year

150 den -> 4200 t/year

200 den -> 5500 t/year

250 den -> 7000t /year

300 den -> 8250 t/year