Barmag FB9-1300-WS/HT

EUROPE (Western and Northern)

Extrusion line type of Raw Material produced : Polyethylene, Polypropylene,

Composed of:

1. Motorized Mixer – 100 kgs per mix capacity,

2. Dosing unit – Hopper 200 kgs capacity, sensor operated, vacuum type,

3. Main Motor/drive – BARMAG, 190 KW,

4. Screw and Barrel – average 6000 kgs/24h capacity (polypropylene),

5. Die – Hanger type, 1340 mm Plastic flow width,

6. Water bath – Cooling system, closed circuit 1000 L capacity,

7. Cutting device – 1340 mm Plastic flow width capacity, ring tape spacers,

8. Oven – Hot air blower type, 90 KW,

9. Goddets – 2 x segment godet from stretching unit to annealing 4 and 6 x rollers, oil, heated, chill roller cooling system,

10. Full Fibrilator system – needle roller capacity length 1300 mm,

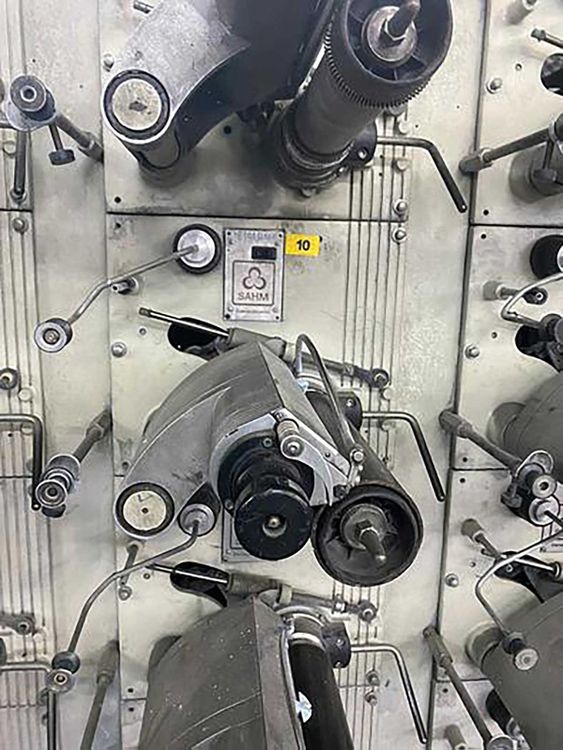

11. Winder Bank – 232 individual SAHM winders type 240E (2001 manufactured),

12. Tape Suction Unit – 2 x motor covering 1 st godet to the last, 2 x entry,

13. Cutting mill/ chipper unit – 1.9 KW rotter type blades single feed to hopper,

14. Thickness control unit – BETACONTROL (2003 manufactured), full software program,

15. BARMAG Full monitoring and control system software