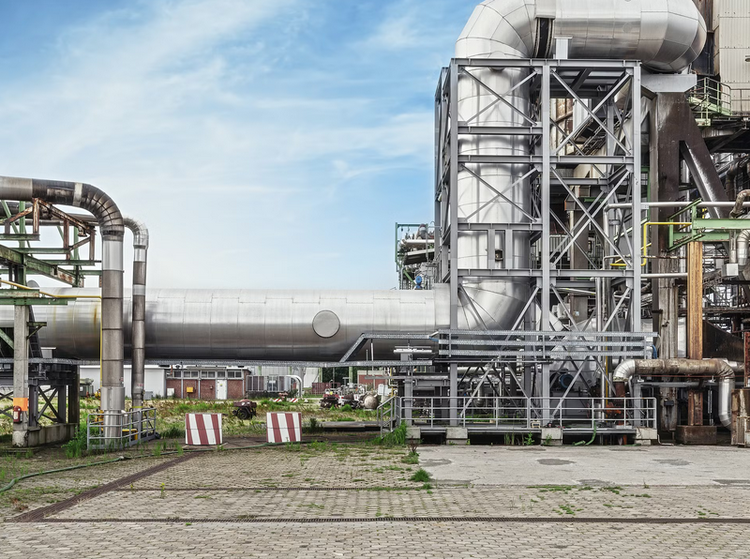

BADGER N.V. Crude Distillation 3 (CD-3)(Combination)

EUROPE (Western and Northern)

BADGER N.V. Crude Distillation 3 (CD-3)(Combination)

Year: 1965

Hilco Industrial offers state-of-the-art BADGER N.V. crude distillation equipment, essential for modern oil refineries.

Atmospheric crude distillation units are designed for optimal performance in separating various petroleum components.

These units employ advanced crude oil atmospheric distillation techniques to efficiently process raw crude into valuable fractions.

Well-maintained atmospheric crude distillation unit from Nynas GmbH in Germany,

a global company specializing in naphthenic specialty oils and bitumen products.

This equipment combines reliability with cutting-edge technology.

Whether you're upgrading existing facilities or building a new refinery,

these crude distillation solutions provide the foundation for your operations.

Crude Oil Atmospheric and Vacuum Distillation and Naphtha Stabilizer.

Year of manufacture 1965

Process Design by Shell

Process Engineering by BADGER N.V.

Feed = Original design, paraffinic crude (21 d/month), naphthenic crude (7 d/month), after 2015 Revamp is 100% naphthenic crudes. Crude oil with Total Acid Number (TAN) up to 4,2 (TJP), 3,3 (Laguna), (range of Viscosity = 5,5 – 144 cst/100°C)

Throughput max. 12.000 t/d – original design

Current Process Parameters (after 2015 Revamp)

Atmospheric Distillation:

Throughput max. 6000 t/d

Operational operating temperature = 355°C

Operational operating pressure = 2,5 bar

Vacuum Distillation:

Throughput = max. 4500 t/d

Operational operating temperature = 380°C

Operational operating pressure = 0,2 bara

Naphtha Stabilizer C-0807:

Throughput = max. 2000 t/d

Operational operating temperature = max. 260°C

Operational operating pressure = max. 14,5 bar

1984 – replacement of middle section of column C-0850 cladded stainless steel (HTAN corrosion protection)

2003 to 2020 – replacement of heat exchanger bundles in cooling water service to duplex steel (corrosion protection)

2009 to 2015 – fugitive emission compliance upgrades of all relevant pump seals, or pump replacements

2009 – Complete retubing of all furnaces and transfer lines to stainless steel (HTAN corrosion)

2015 – major revamp to process 100% naphthenic crude oil @ 6000 t/d, new furnace stack, conversion to natural gas firing, new top section C-0851 to cladded stainless steel, upgrade of piping above 240 °C to stainless steel (HTAN corrosion)

2020 – new top section of vacuum column C-0850 to cladded stainless steel, further upgrade of piping above 210 °C to stainless steel (HTAN corrosion)

2022 – Decommissioning