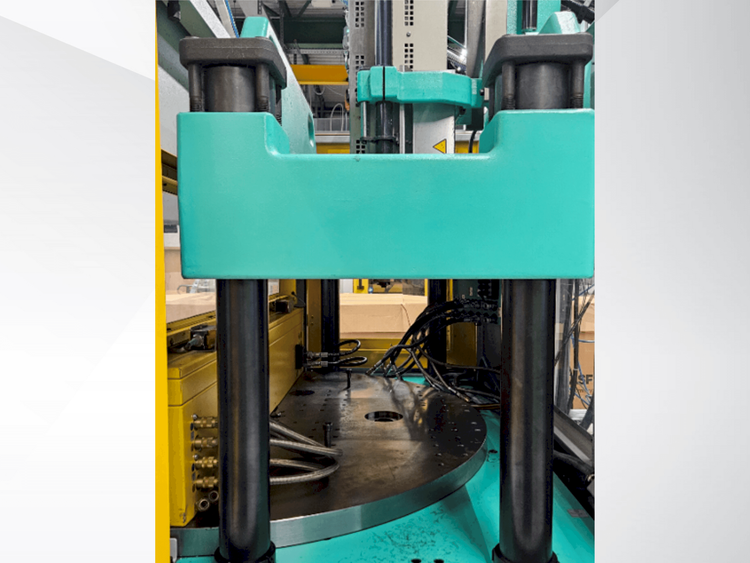

Arburg Allrounder 1500 T 2000-400 200 T

EUROPE (Western and Northern)

This vertical injection moulding machine was manufactured in

2013. It features a clamping force of 2000 kN and a

table diameter of 1500mm. The screw diameter is 40mm,

with a maximum injection pressure of 2000 bar.

It efficiently handles material throughput at 29 kg/h PS.

Ideal for precision moulding, the Arburg Allrounder 1500 T

2000-400 represents a robust addition to any production line.

Overview

BRAND: ARBURG

YEAR: 2013

MODEL: ALLROUNDER 1500 T 2000-400

APPLICATION TYPE: INJECTION MOULDING

MACHINE TYPE: VERTICAL INJECTION MOULDING MACHINE

INJECTION UNIT

SCREW DIAMETER: 40 MM

SHOT WEIGHT: 184 G PS

STROKE VOLUME: 201 CM3 CM³

INJECTION PRESSURE: 2000 BAR

CLAMPING UNIT

CLAMPING FORCE: 2000 KN

MOULD HEIGHT MIN: 400 MM

EJECTOR FORCE FOR / BACK: 25|175 KN|MM

Additional Information

TECHNICAL MACHINE BENEFITS:

- OPENING FORCE MAX. : 115 | 300 KN|MM

- PALLET DISTANCE FIXED: 700 MM

- TABLE DIAMETER: 1500 MM

- ROTATION ANGLE LEFT/RIGHT: 180°

- WEIGHT OF MOVING MOULD HALF: 500 KG

- EFFECTIVE SCREW LENGTH: 20 L/D

- SCREW STROKE: 160 MM MAX.

- MATERIAL THROUGHPUT: 29 KG/H PS

- HOLDING PRESSURE MAX. : 2000 BAR

- INJECTION FLOW² MAX. : 168 CM³/S (2 PUMPS)

QUALITATIVE MACHINE BENEFITS:

- SCREW CIRCUMFERENTIAL SPEED² MAX. : 53 M/MIN (2 PUMPS)

- SCREW TORQUE MAX. : 550 NM

- NOZZLE CONTACT FORCE|-LIFT-OFF MOVEMENT MAX. : 60 | 400 KN|MM

- GRANULATE CONTAINER: 50 LITRES

- ROTARY TABLE: YES (180° ROTATION ANGLE LEFT/RIGHT)

- COMPREHENSIVE INJECTION UNIT WITH

HIGH INJECTION PRESSURE AND MATERIAL THROUGHPUT

- ROTARY TABLE WITH 180° ROTATION ANGLE FOR

EFFICIENT MOULDING

EXTRA INFORMATION

- MACHINE STILL UNDER POWER