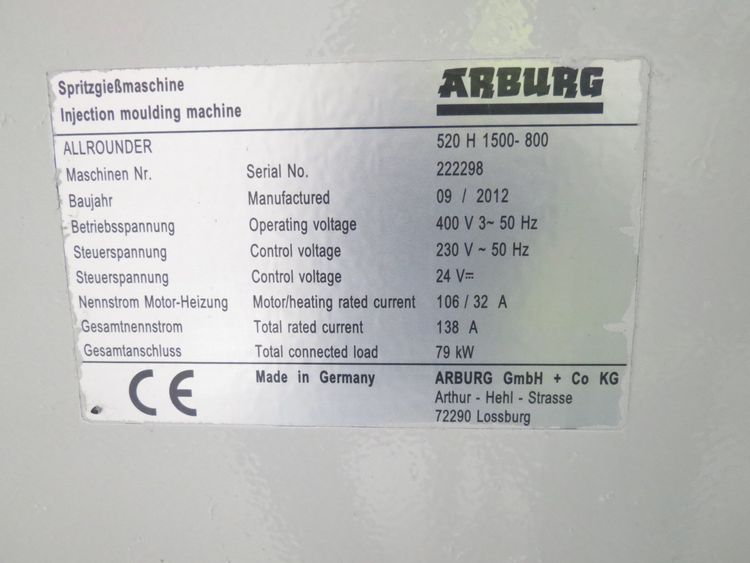

Arburg A 520 H 1500-800 HIDRIVE (Hybrid) 150 T

EUROPE (Western and Northern)

Only 37,500 h

Screw diameter: 50 mm

Injection weight in polystyrene: 359 g/PS

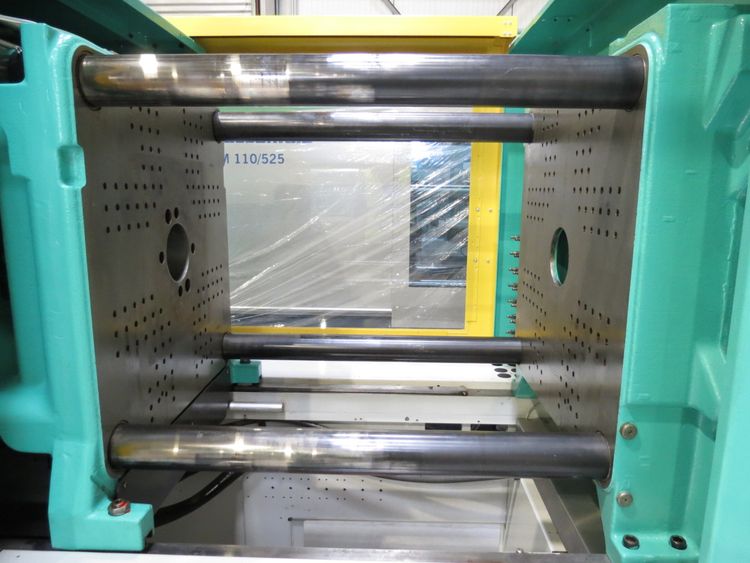

Clamping force: 1500 kN

Bar spacing: 520 x 520 mm

Mould installation height - min./max.: 250 / 550 mm

Control: Selogica

Plate spacing - max.: 650 - 950 mm mm

Machine weight approx.: 6.5 t

Space required approx.: 5.20 x 1.60 x 2.00 m m

H series

- reinforced screw coupling

Multi-tooth coupling geometry

- Cylinder extended with barrier screw

- Injection unit adapted for extended. Plasticizing units

- Drive unit with 15 kW motor and 29.1 l/min

loading volume flow

- Selogica control

- Storage drive technology level

- Electrical connection pneumatic NVD 1 in the tool

- Servo-electric mold height adjustment with

automatic closing force control

- Blow-out device 1 with pressure reducer

- Blow-out device 2 with pressure reducer

- Core pull, simultaneous travel movement P/Q

controlled, programmable

- Core pulls with max. volume flow of 100 l/min.

- Continuous oil cooling and filtration

- Nozzle contact force controlled

- Robot system interface (according to EUROMAP 67)

50-pin

- Master computer interface

- Printer interface serial USB

- 4 programmable inputs and outputs on terminal block

- Compact Flash interface for data record storage

- Operator authorization with chip card according to

EUROMAP 65

- AED - electrom. Dosing drive

- Injection with tool closing ("flying injection")

- Coloring device interface

- Arburg equipment packages no.: 1,2,3,5,6,7

- Control Screw Pilot

- Hydraulic accumulator

- Ejector plate safety connection

- Machine-related cooling circuits regulated

- Protective device open at the top

This machine was partially overhauled,

cleaned and functionally tested in our company

Cleaning of the machine

Sealing of leaks

Use of new hydraulic hoses

Overhaul of the plasticizing unit with use of new heating bands

Use of a new hydraulic accumulator

Defective parts were replaced

Painting of the machine

Functional test of the machine

Test run of the machine

Adjustment of the machine