26 Dietze & Schell Winders EW800

EUROPE (Western and Northern)

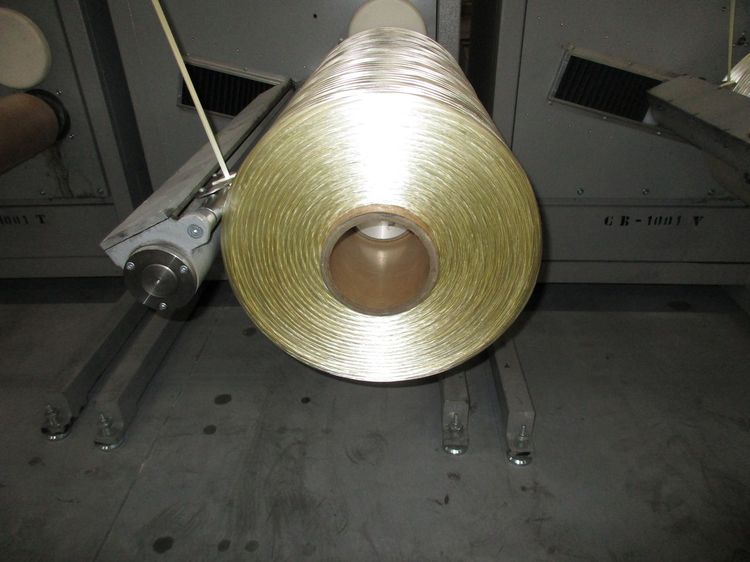

Model EW 800 - 26 winders (adequate to spool tows from 1k to 80k and produce spools with a maximum weight of 350 kg)

The winders are not assembled.

The 26 Winders are controlled by 3 control panel divided in 8+9+9 winders.

Control panel 1 (8 winders) is the MAIN CONTROL PANEL which means to assemble one of the others set of winders (9) you need always to have the main control panel assembled.

If, by any case, you’d want to assemble the winders in different locations you’d have to ensure they all have communication with control panel 1.

Without control panel 1 you can't run other control panels. therefor spliut sale is not possible.

Machine specification:

- drive by reinforced threephase A.C. motor 1,1 kW, 6-pole in connection with frequency converter

- tension controller adjustable for tension ranges from 200 to 2.500 g for 3-48 K or 600 up to 4800 g, with exchange pneumatic cylinder for 48-72 K, with adjustability of a relaxing yarn tension via proportional pressure regulation valve, pre-selectable via display

- Winding speed range 35 - 120 m/min.

- starting speed from 10 mlmin.

- 1 input terminal for input, control and display of production data in main cabinet on line end

- Line-speed-signal data-exchange to Precursor Machines either via analog-signals or communication-protocol (CC-Link, Device-Net or Profibus)

- Data-exchange to Auto-doffing-robot (line machine number, winding period, doffin9-time, bobbin-weight, operator login, winder-no., yarn length); Exact protocol has to be specified.

- Oracle database is not in the scope from Dietze & Schell

- HMI-terminal used for receipes, alarms;

- If communication between HMI and winder fails, winder should continue to run

- first deflection roller adjustable

- traverse mechanism with double grooved scroll cam for traverse length of 800 mm

- support for traverse box with linear movement

- traverse mechanism with separate drive

- pressure roller with special surface finishing - upgraded version with shafts for easy bearing remount

- maximum package diameter up to approx. 800 mm for the production of packages of max. 350 kg

- pressure load onto the package adjustable by compressed air via air cylinder from 2 to 14 kg, adjustability of counter pressure via proportional pressure regulation valve pre-selectable via display

- special winding arbor suitable for plastic or paper tubes 144+1 mm inside diameter x 820 +/- 1 mm long, outside diameter 164 +/- 0,5 mm – MODIFIED to 134 inside diameter x 852 MM long, outside diameter 157MM

- bobbin push-off system to push the full package forward on the spindle for easier doffing, see enclosed layout drawing

- reverse stop for influence of package formation with improved connection parts

- prior notice and notice of full package

- yellow lamp for prior notice (blinking) and full package and red lamp for yarn breakage

- crossing ratio adjustable via display

- starting of the winder by button

- stopping by pressure button

- spindle braking device

- height of top roller approx. 1900 mm

- all compressed air action calculated for a max. pressure of 6 bar

- spindle height approx. 676 mm

- hoses for pressure air made of Polyurethane

- suction device with hand lever at machine

- time counter and meter counter at machine

- all rolls coated mat hard chrome with orange peel effect Machine mounted on a frame

Winder height : ca.1900mm

Frame width : 910 mm

Weight : ca 480kg

Winding material (PAN) 3K up to 72K

Max spindle rotation seed 540 1/min

supply voltage - 3 N PE 400 V 50 Hz