14 Sulzer P7100 190 Cm Cam, dobby

ASIA (North East)

For tire cord fabrics.

On production, delivery May 2024

2x P7100 W 190 N4 SP D1, Year 1990

2 and 4-Color Weft Insertion

with STAUBLI 2035-KR4 Dobby Mechanical Dobby for 14 drives.

1x P7100 S 190 N1-1 EP D1, Year 1990

Weft Mixing Weft Insertion

with Positive Cam Shedding Motion for 6 drives.

5x P7100 S 190 N2 EP Q D1, Year 1991-92

2-Color Weft Insertion

with Positive Cam Shedding Motion for 6 drives.

1x P7100 B 190 N2 EP Q R D12, Year 2001

2-Color Weft Insertion

with Positive Cam Shedding Motion for 10 drives.

1x P7100 S 190 N2 EP Q D12, Year 1994

2-Color Weft Insertion

with Positive Cam Shedding Motion for 6 drives.

3x P7100 S 190 N2 EP W D1, Year 1993

2-Color Weft Insertion

with Positive Cam Shedding Motion for 6 drives.

1x P7100 S 190 N4 EP Q D1, Year 1995

4-Color Weft Insertion

with Positive Cam Shedding Motion for 6 drives.

* Automatic/Electronic Let-Off by SULZER for 1 width warp beam

800mm flange dia., including 1.0pcs warp beams per machine

* with whip roll with brake

* Electronic warp stop motion, for 6 banks of drop wires, type asymmetric

* Electronic weft stop motion, type LOEPFE (SFWL)

* 2 "Savitech" weft accumulators with 1 control box

* 2 Electronic Weft Air Brake (on 2sets W190)

* Positive shedding motion, for 6 heddle-frames with 12mm pitch

* Drive of the heddle-frames controlled by Tappet for the positive drive of the

heald frames for a maximum of 6 picks repeat

* Pick finding device with the automatic reversing of the take-up motion

* 1 type pick counter for 4 shifts of Sulzer

* 1 motor, type 4.25kw, 200V/60Hz, upto 430 picks per min.

max. insertion rate 790 meter per min.

* 6 heddle-frames, type Grobamextra with 330ED separators

* 6 tappet cams, 1/1 + 1/1

* 1.5 cloth roller per machine

* 1 set of shuttles (projectiles), clamping force 2200gr, 11pcs installed

* 1 weft package support 2 color-wagon for Profi (Savitech Made)

* 1 weft stop motion, electrial detector

* 1 pair of temples,

* 7000 droppers and heddles (about), quantiy is per on machine

* 1 set of cone holders for 4 cones, 54mm bore of the cone

* 1 tuck-in selvedge device on left and right side

* 1 lot of guide teeth, type half-half

* 1 pressure roller 133mm dia. with drive

* 1 take-up by helical gear

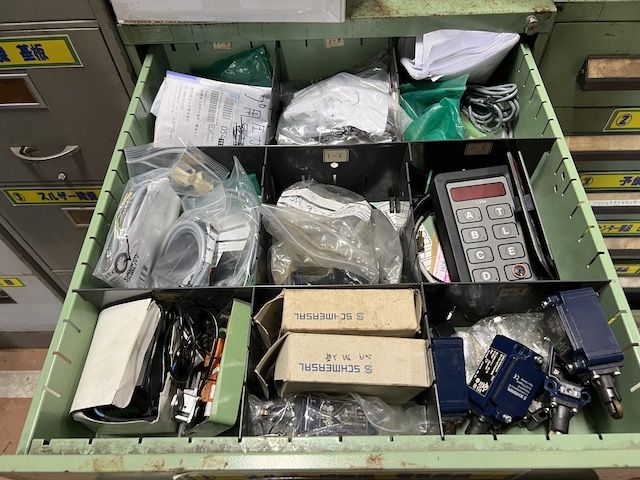

* 1 Swiss Sulzer Multi-card Control Box